Development and Testing of a Wave Powered Offshore Sensing System

Slide 1

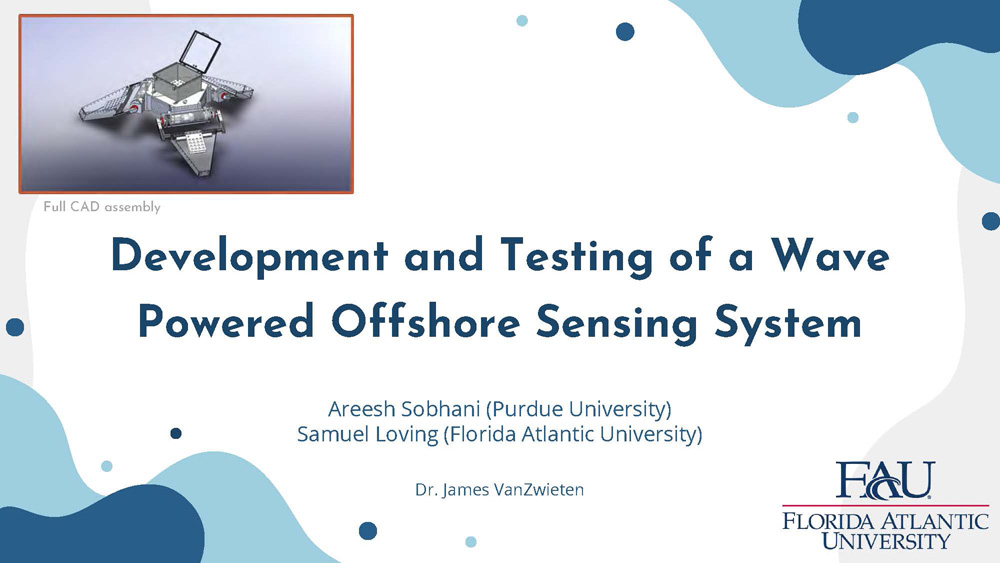

Development and Testing of a Wave Powered Offshore Sensing System

Areesh Sobhani (Purdue University)

Samuel Loving (Florida Atlantic University)

Dr. James VanZwieten

The slide shows a 3D CAD rendering of a wave energy converter system with multiple components including what appears to be a cylindrical buoy structure with internal mechanisms and wing-like appendages extending from the sides.Image caption: Full CAD assembly

Slide 2

80,000 TW/Year

~800,000,000,000,000 A19 10W LED Lightbulbs

Slide 3

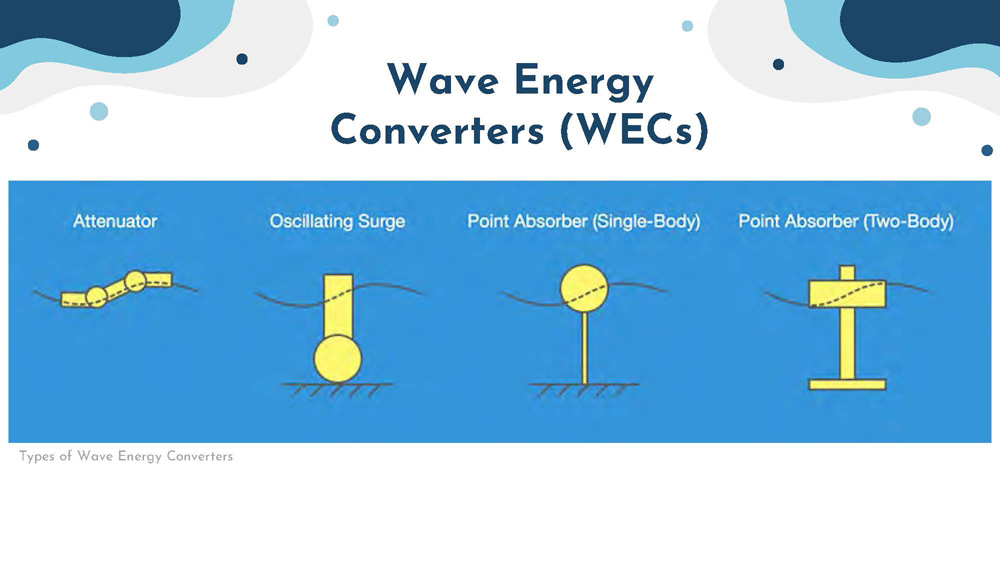

Wave Energy Converters (WECs)

Types of Wave Energy Converters

This slide displays various types of wave energy converter designs including different mechanical configurations and deployment methods. The images show different WEC technologies including oscillating water columns, point absorbers, attenuators, and overtopping devices.

Slide 4

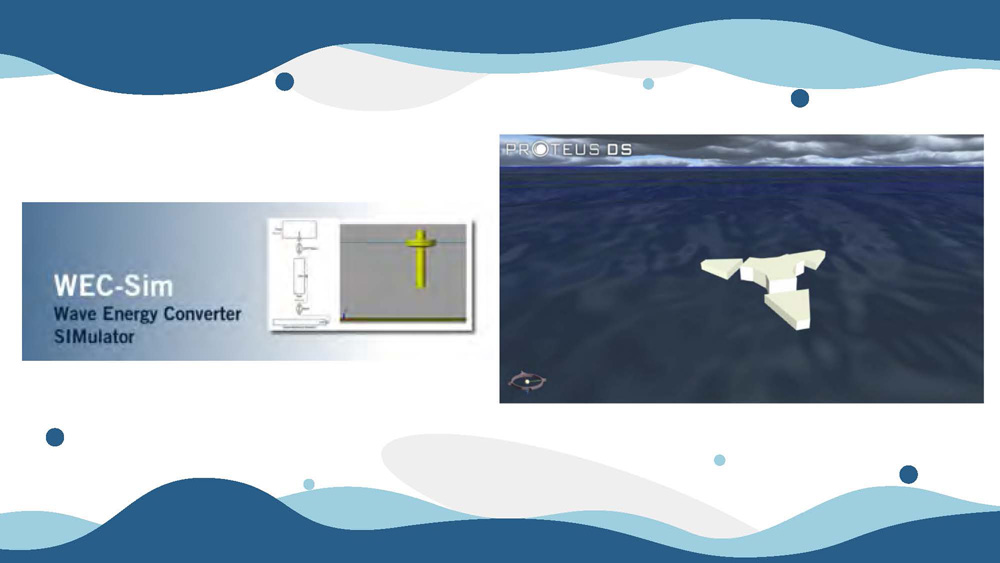

The image is divided into two sections

• The left section shows a graphic with the text “WEC-Sim Wave Energy Converter SIMulator.” It includes a small diagram of a vertical structure with a yellow horizontal element.

• The right section shows a computer-generated image labeled “PROTEUS DS” at the top, displaying a white, angular object floating on a dark blue water surface under a cloudy sky.

Slide 5

Knowledge and Development Gaps

Simulation Validation

Validation of Electrical and Mechanical Power Ratings, as well as optimization of the two characteristics

Performance Characterization

Wave Characterization to Record Performance in different environmental circumstances

System Repair, Maintenance, and Upgrades

Improving the testbed to record reliable data

Slide 6

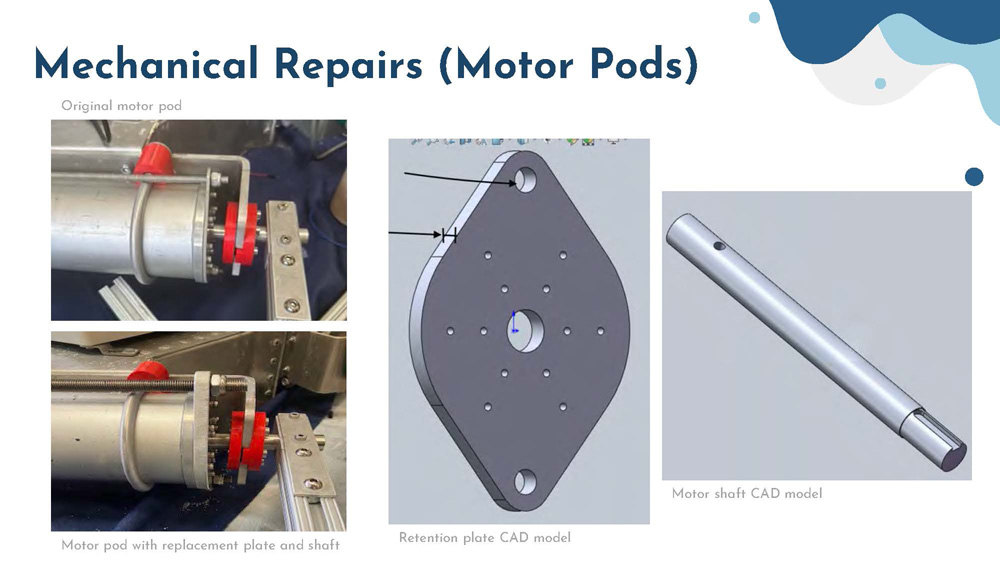

Mechanical Repairs (Motor Pods)

Original motor pod

Motor pod with replacement plate and shaft

Retention plate CAD model

Motor shaft CAD model

This slide shows detailed CAD renderings of the retention plate, motor shaft, and comparison between original and updated motor pod designs.

Slide 7

Mechanical Repairs & Upgrades (Motors)

Original motor

Replacement motor, fitted with a brace and connectors

Brace CAD model

Brace leak sensor slot

The slide displays photographs of the original motor compared to the replacement motor with additional bracing and connectors. The CAD model shows the detailed design of the brace including the leak sensor slot integration.

Slide 8

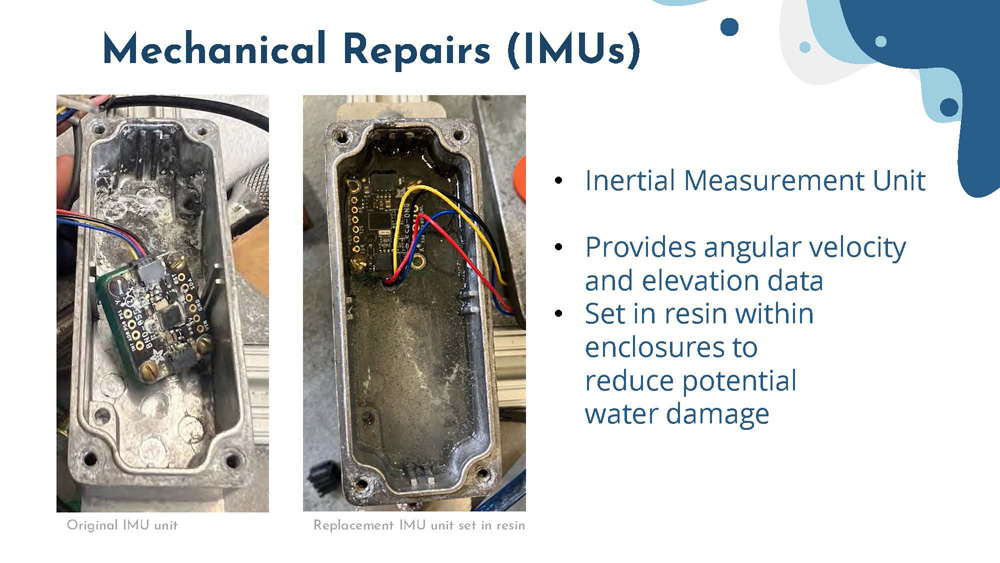

Mechanical Repairs (IMUs)

- Inertial Measurement Unit

- Provides angular velocity and elevation data

- Set in resin within enclosures to reduce potential water damage

Original IMU unit

Replacement IMU unit set in resin

This slide shows the protection improvements made to the Inertial Measurement Units, comparing the original unit to the upgraded version that has been encapsulated in resin for better water resistance. The IMUs are critical sensors that measure the motion characteristics of the wave energy converter.

Slide 9

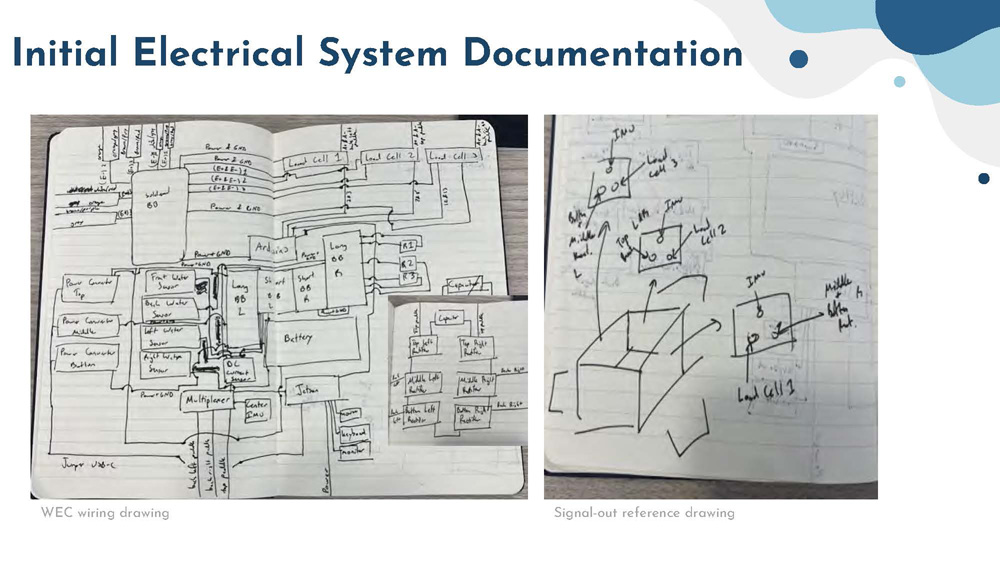

Initial Electrical System Documentation

WEC wiring drawing

Signal-out reference drawing

The slide presents technical diagrams documenting the electrical connections and signal pathways in the wave energy converter system. These engineering drawings show the interconnections between various system components and the signal output configurations.

Slide 10

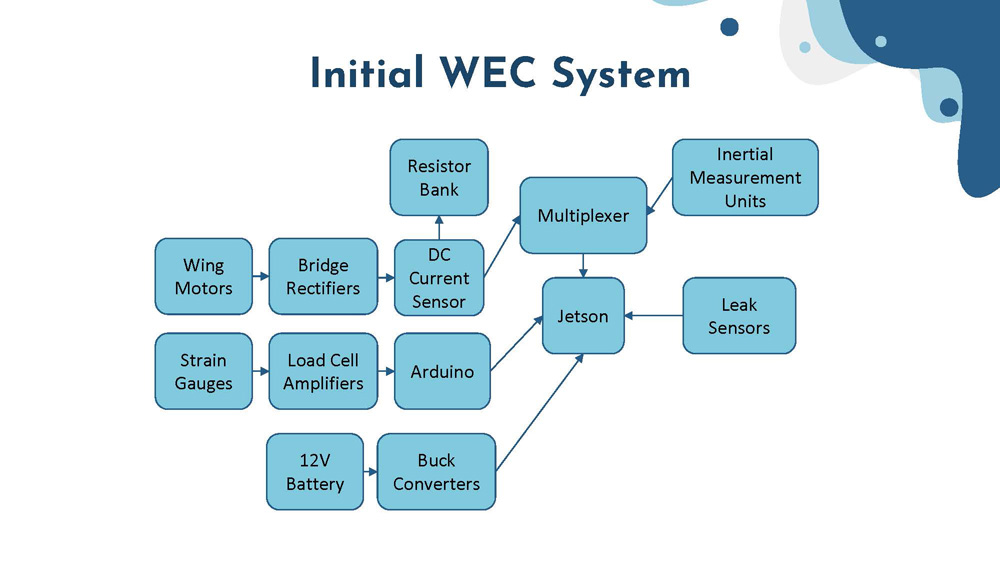

Initial WEC System

The system diagram shows interconnections between the following components:

- Jetson

- Arduino

- Load Cell Amplifiers

- Strain Gauges

- Wing Motors

- Buck Converters

- Multiplexer

- Inertial Measurement Units

- DC Current Sensor

- Resistor Bank

- Bridge Rectifiers

- 12V Battery

- Leak Sensors

This block diagram illustrates how all the major electrical and electronic components of the wave energy converter are interconnected, showing the flow of power and data throughout the system.

Slide 11

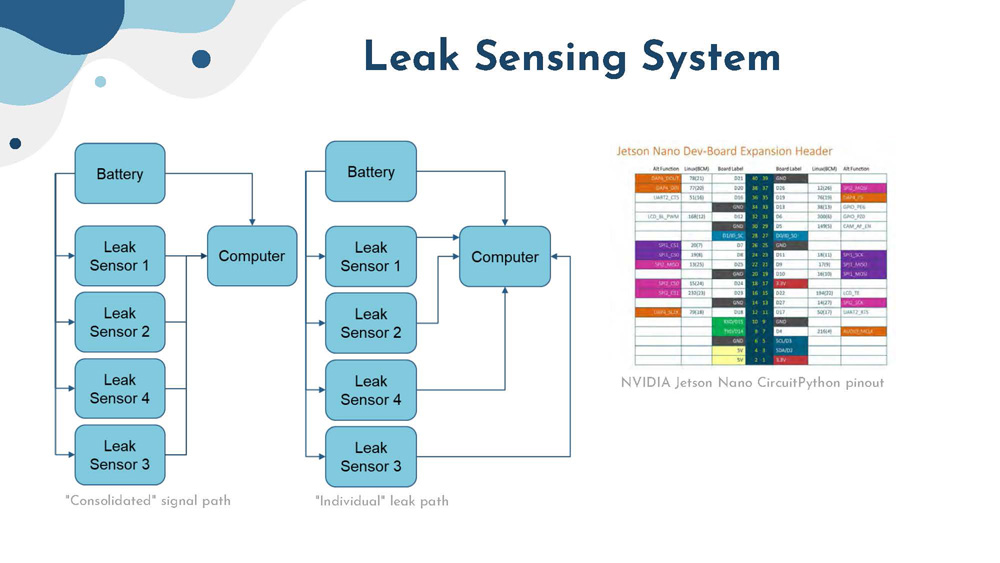

Leak Sensing System

"Consolidated" signal path

"Individual" leak path

NVIDIA Jetson Nano CircuitPython pinout

This slide details the leak detection system implementation, showing both consolidated and individual signal path configurations. The circuit diagrams demonstrate how leak sensors are connected to the NVIDIA Jetson Nano controller, with pinout information for the CircuitPython programming interface.

Slide 12

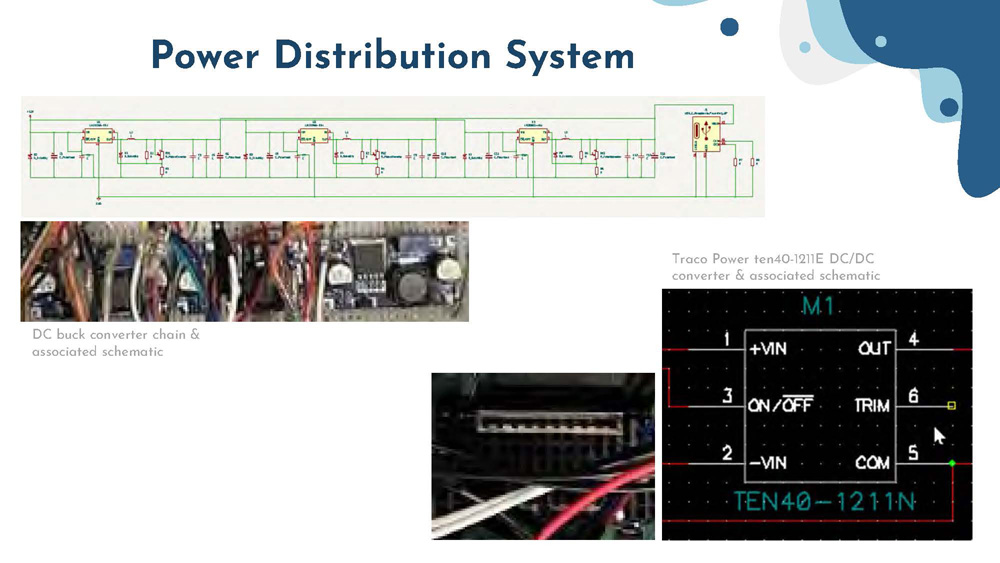

Power Distribution System

DC buck converter chain & associated schematic

Traco Power ten40-1211E DC/DC converter & associated schematic

The slide shows the power management system design, including detailed schematics of the DC buck converter chain and the Traco Power DC/DC converter.

Slide 13

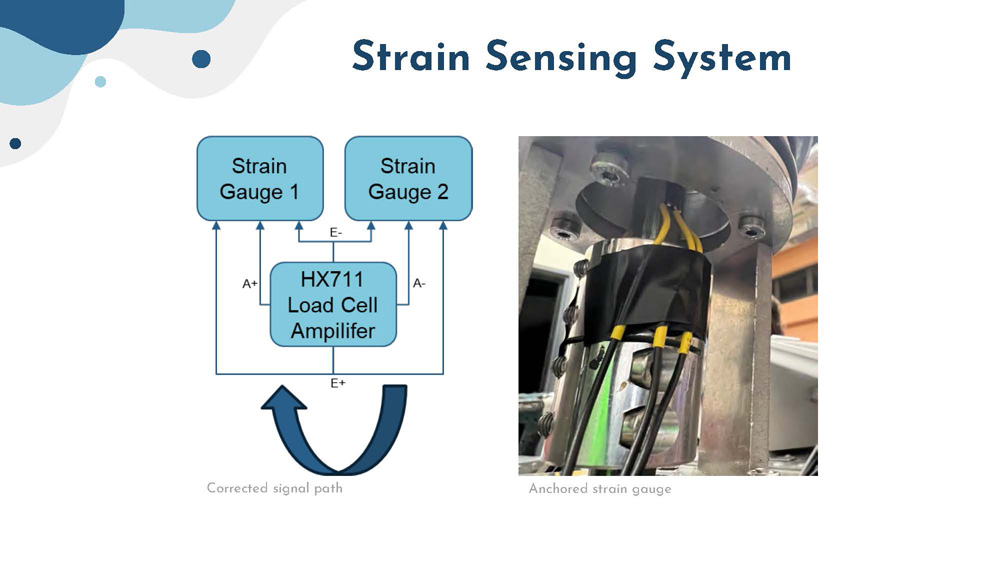

Strain Sensing System

Corrected signal path

Anchored strain gauge

This slide presents the strain measurement system, showing both the electrical signal path diagram and a photograph of the physically installed strain gauge.

Slide 14

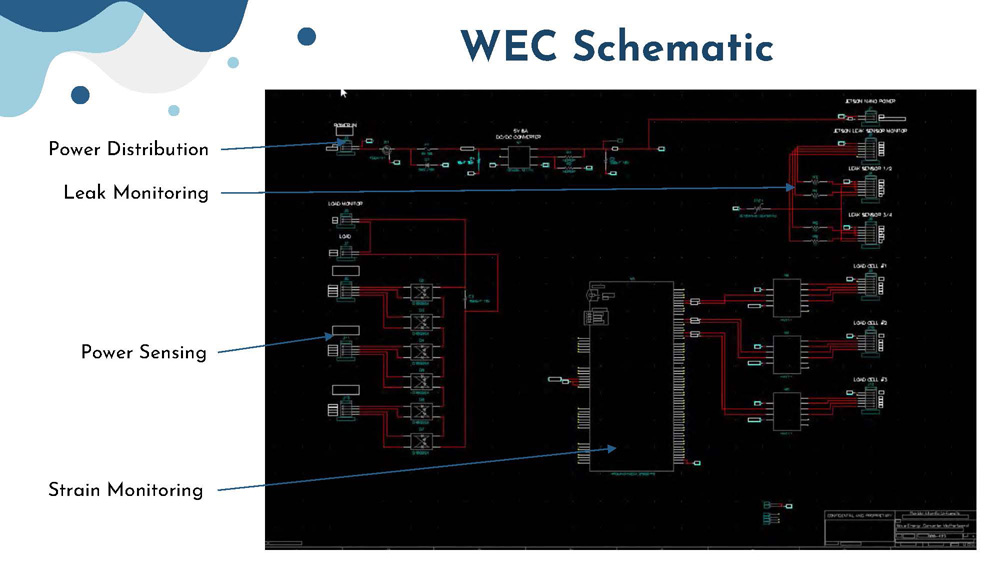

WEC Schematic

- Power Distribution

- Power Sensing

- Strain Monitoring

- Leak Monitoring

This comprehensive schematic diagram shows the complete wave energy converter system architecture, integrating all subsystems including power distribution, power sensing, strain monitoring, and leak monitoring. The diagram illustrates how these various subsystems work together in the overall WEC design.

Slide 15

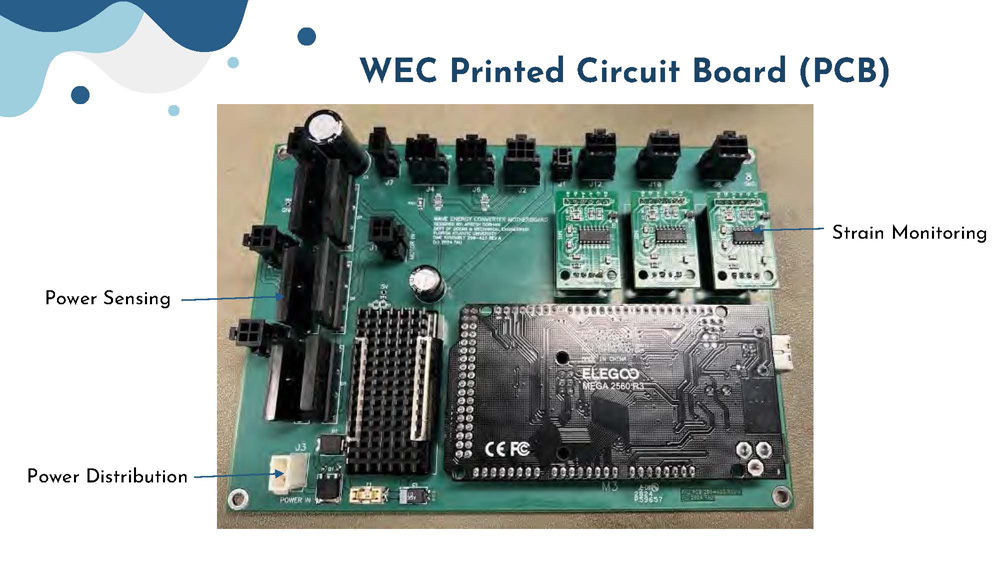

WEC Printed Circuit Board (PCB)

- Strain Monitoring

- Power Sensing

- Power Distribution

This slide shows the custom printed circuit board designed for the wave energy converter, highlighting the sections dedicated to strain monitoring, power sensing, and power distribution.

Slide 16

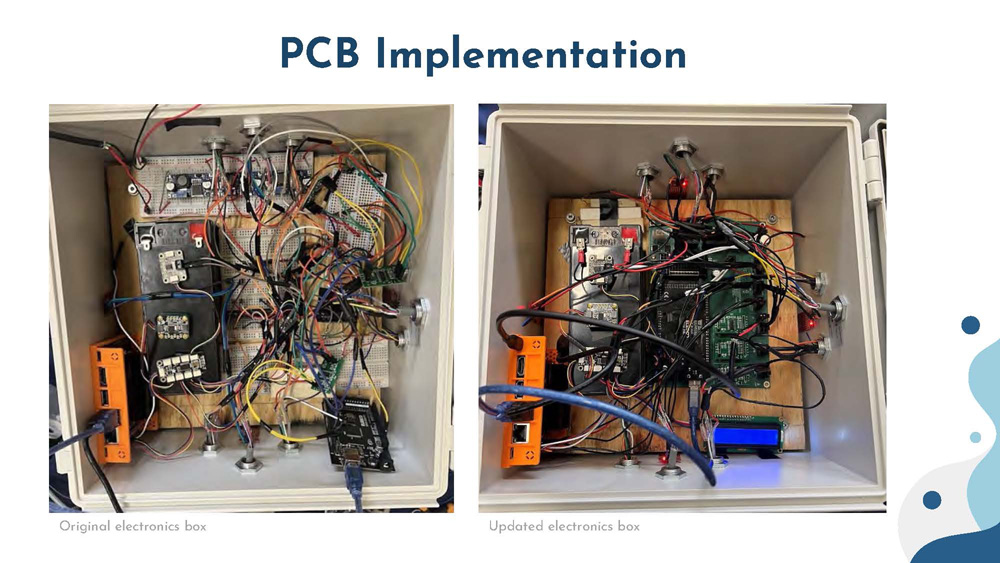

PCB Implementation

Original electronics box

Updated electronics box

The slide compares the original electronics enclosure with the updated version that houses the new PCB. The photographs show the evolution of the electronics packaging, demonstrating improvements in organization and integration of the control systems.

Slide 17

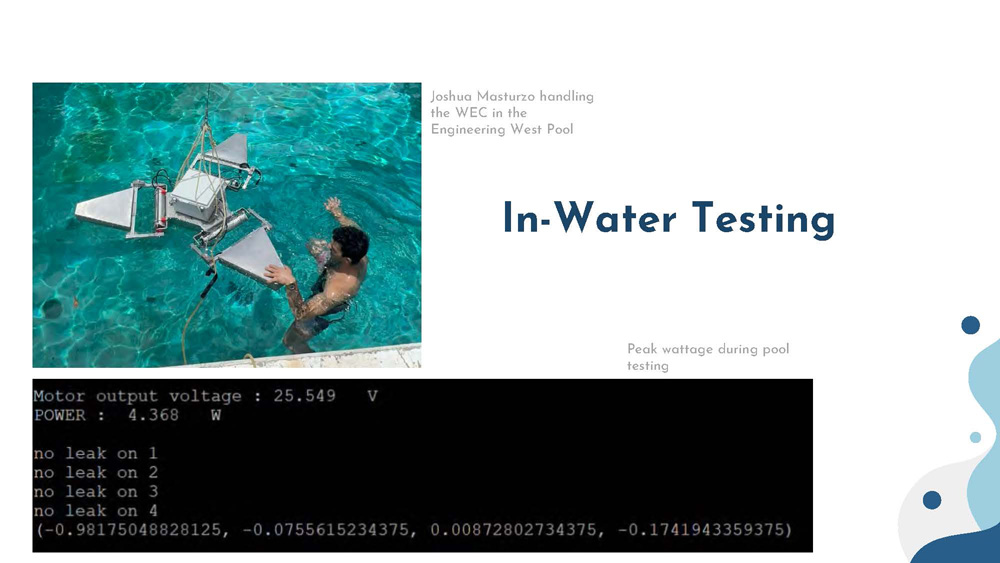

In-Water Testing

Peak wattage during pool testing

Joshua Masturzo handling the WEC in the Engineering West Pool

This slide shows a graph of peak wattage measurements during pool testing alongside a photograph of team member Joshua Masturzo working with the wave energy converter in the Engineering West Pool.

Slide 18

Going Forward

- 01 Gen2 Layout

- 02 Strain Gauge System

- 03 Re-simulation

- 04 High-Vol Test Data

- 05 System Buoyancy

This slide outlines the five key areas for future development of the wave energy converter system.

Slide 19

Acknowledgments

- Dr. James VanZwieten

- Joshua Masturzo

- James Laumeyer

- Ed Henderson

This slide recognizes the key team members and contributors who made this wave energy converter research project possible.

Slide 20

References

DePietro, A. R. (2022, May). Numerical Simulation and Performance Characterization of Two Wave Energy Converters.

DiversiTech. (2024). 3/4IN. X 60FT. ECONOMY ELECTRICAL TAPE 10/PK. DiversiTech. Retrieved 2024, from https://www.diversitech.com/tape-econelectape-34x60ft.

Microsoft. (n.d.). PuTTY. Microsoft Store. Retrieved July 24, 2024, from https://apps.microsoft.com/detail/xpfnzksklbp7rj?amp%3Bgl=US&hl=en-us&gl=US.

NREL. (2021). WEC Sim Header. OpenEI. OpenEI. Retrieved July 24, 2024, from https://openei.org/wiki/WEC-Sim.

NVIDIA. (n.d.). Getting Started with Jetson Nano 2GB Developer Kit. NVIDIA Developer. Retrieved July 24, 2024, from https://developer.nvidia.com/embedded/learn/get-started-jetson-nano-2gb-devkit.

Oubit. (n.d.). Step Motor Stepper 57 Steps 3.0Nm Large Torsion Low Noise High Speed for Equipment, Closed Loop Stepper Motor for CNC Mill Lathe Router. Amazon. Retrieved July 24, 2024, from https://www.amazon.com/Stepper-Torsion-Equipment-Closed-Router/dp/B0B5QFMMQ8.

Plate, T. (2022). New Tool Helps Researchers Make the Most of Wave Power. NREL. NREL. Retrieved 24AD. Wave power. (n.d.). Wikipedia. Retrieved July 24, 2024, from https://en.wikipedia.org/wiki/Wave_power.

End of Presentation

Click the right arrow to return to the beginning of the slide show.

For a downloadable version of this presentation, email: I-SENSE@FAU.