Bio Robotics: Wearable Prosthetics

Slide-1

Bio Robotics: Wearable Prosthetics

Presented by Jocelyn Daniel, Biotechnology, University of Central Florida

and Daniela Delgado,

Computer Science, Middlebury College

Slide-2

Worldwide Impact

- 30 million people worldwide

- 1 in 1,900 babies in the United States

Slide-3

Focused Impact

Create an economical and environmentally friendly wearable device that is up to date with today's technology

Slide-4

Environmentally Favorable

Poly-Lactic Acid (PLA)

- Biodegradable

- Less carbon emissions

- Easier to work with

Polyethylene terephthalate glycol (PETG)

- Long lasting

- The smoke is carcinogenic

- More expensive overall

- Used in production of consumer products

Slide-5

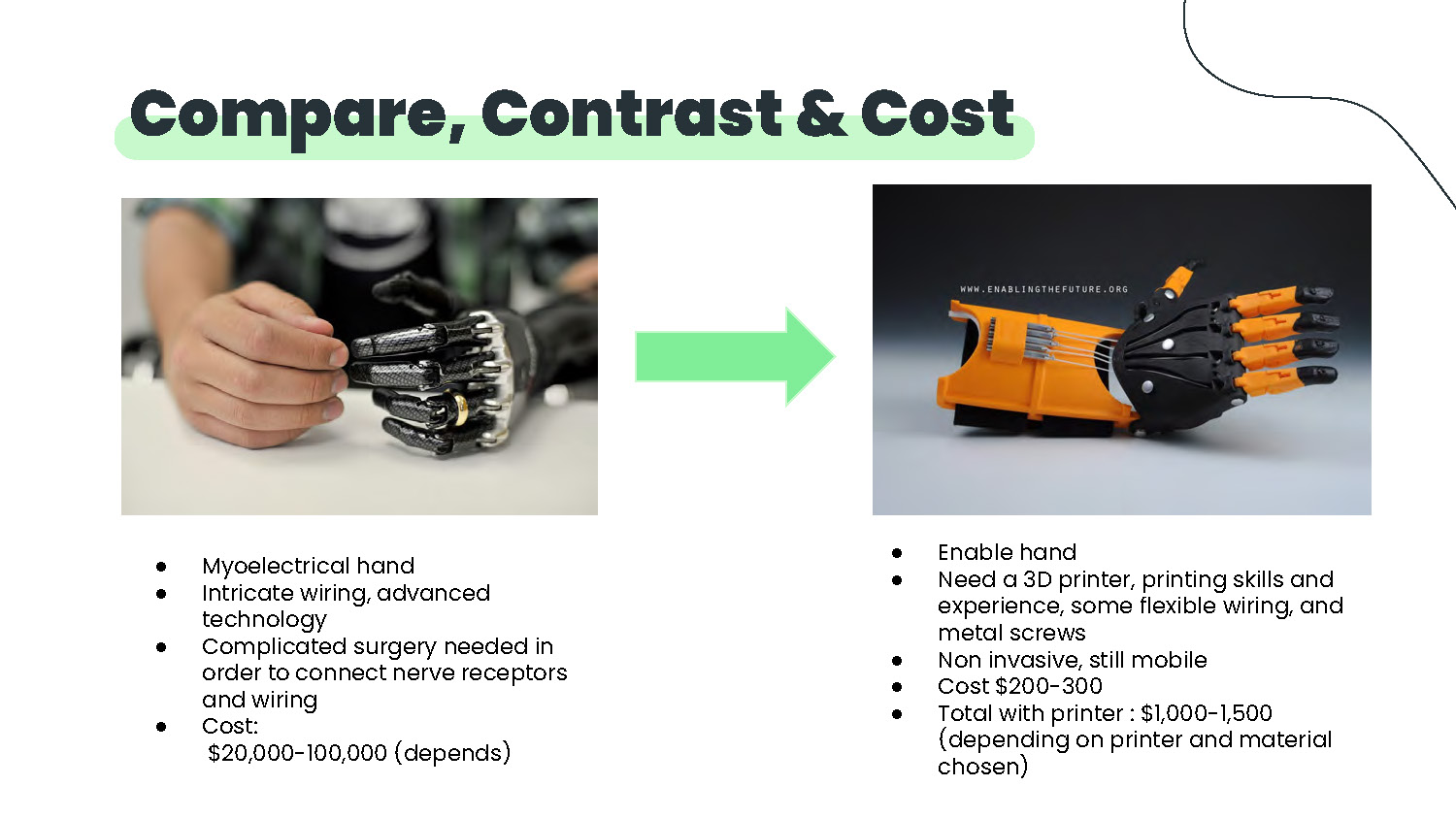

Compare, Contrast & Cost

Myoelectrical hand

- Intricate wiring, advanced technology

- Complicated surgery needed in order to connect nerve receptors and wiring

- Cost: $20,000-100,000 (depends)

Enable hand

- Need a 3D printer, printing skills and experience, some flexible wiring, and metal screws

- Non invasive, still mobile

- Cost $200-300

- Total with printer: $1,000-1,500 (depending on printer and material chosen)

Slide-6

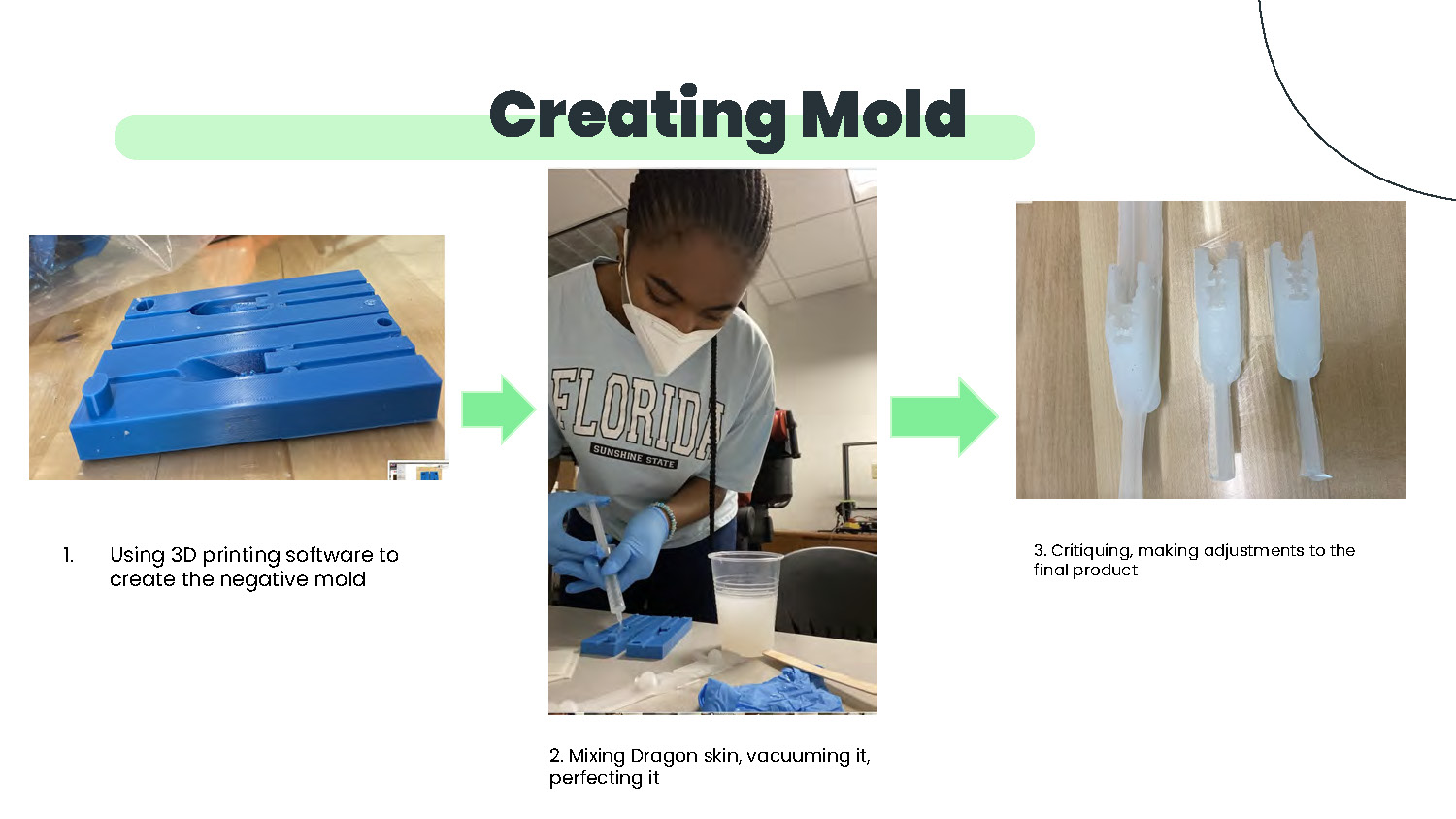

Creating Mold

- Using 3D printing software to create the negative mold

- Mixing Dragon skin, vacuuming it, perfecting it

- Critiquing, making adjustments to the final product

Slide-7

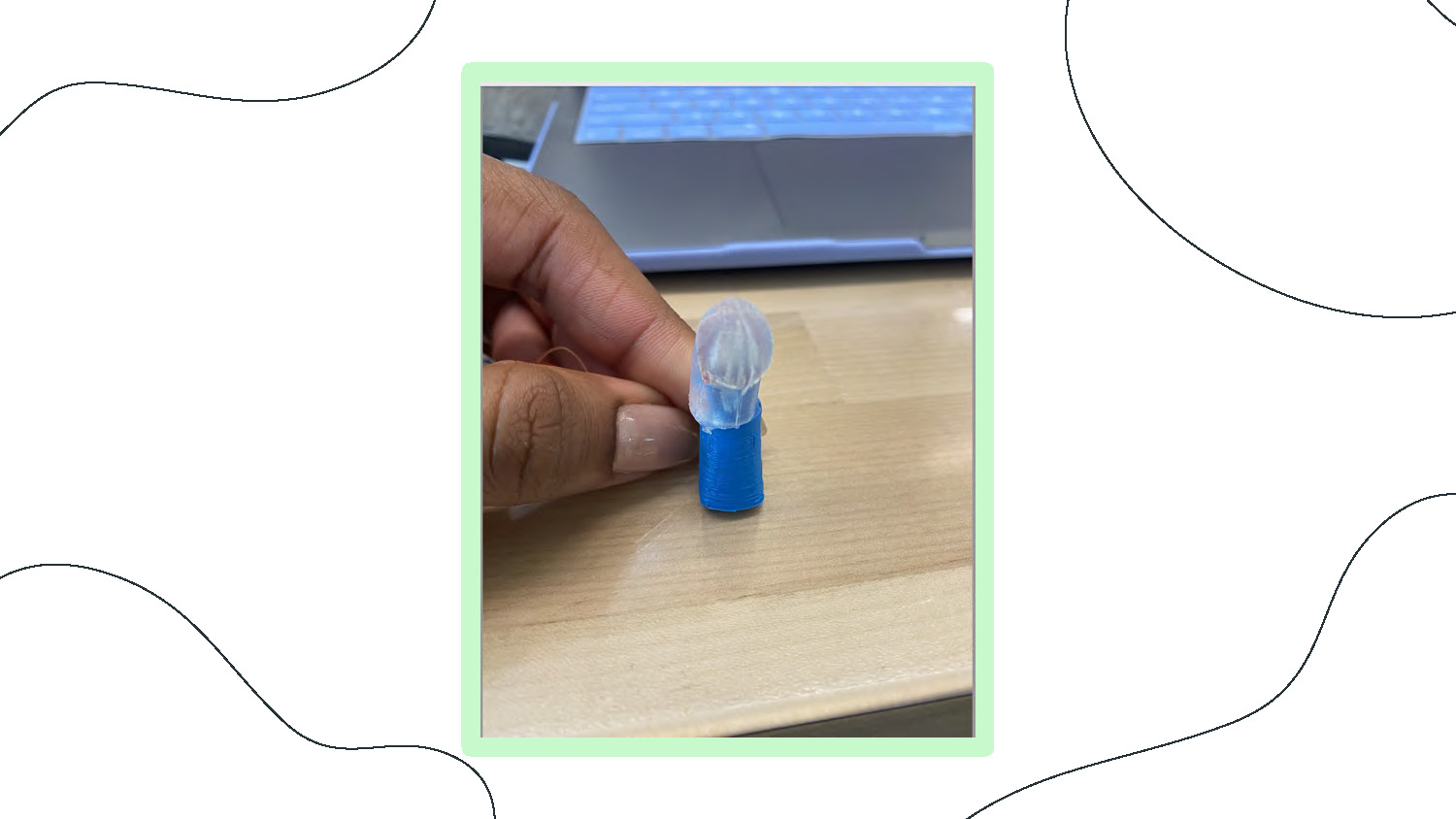

A person's hand with manicured fingernails holds a small, two-part object. The object consists of a translucent, frosted top piece shaped like a dome with a wavy bottom edge, and a solid blue cylindrical base. The hand is holding the blue base between the thumb and index finger. The object is positioned over a light-colored wooden surface, with a laptop keyboard and a black cord partially visible in the blurred background. The image is taken at a slight downward angle, focusing on the hand and the object.

Slide-8

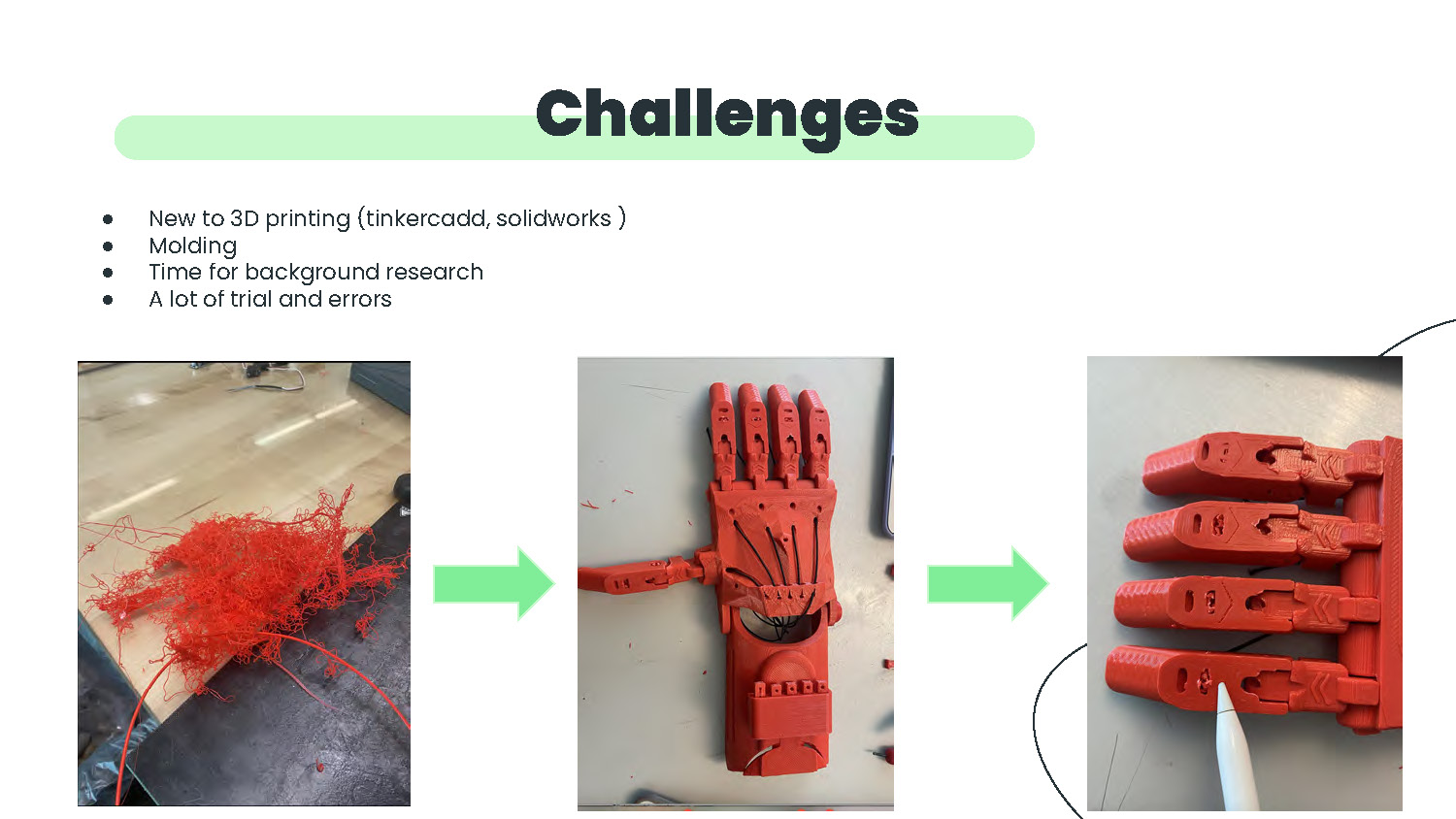

Challenges

- New to 3D printing (tinkercadd, solidworks)

- Molding

- Time for background research

- A lot of trial and errors

Slide-9

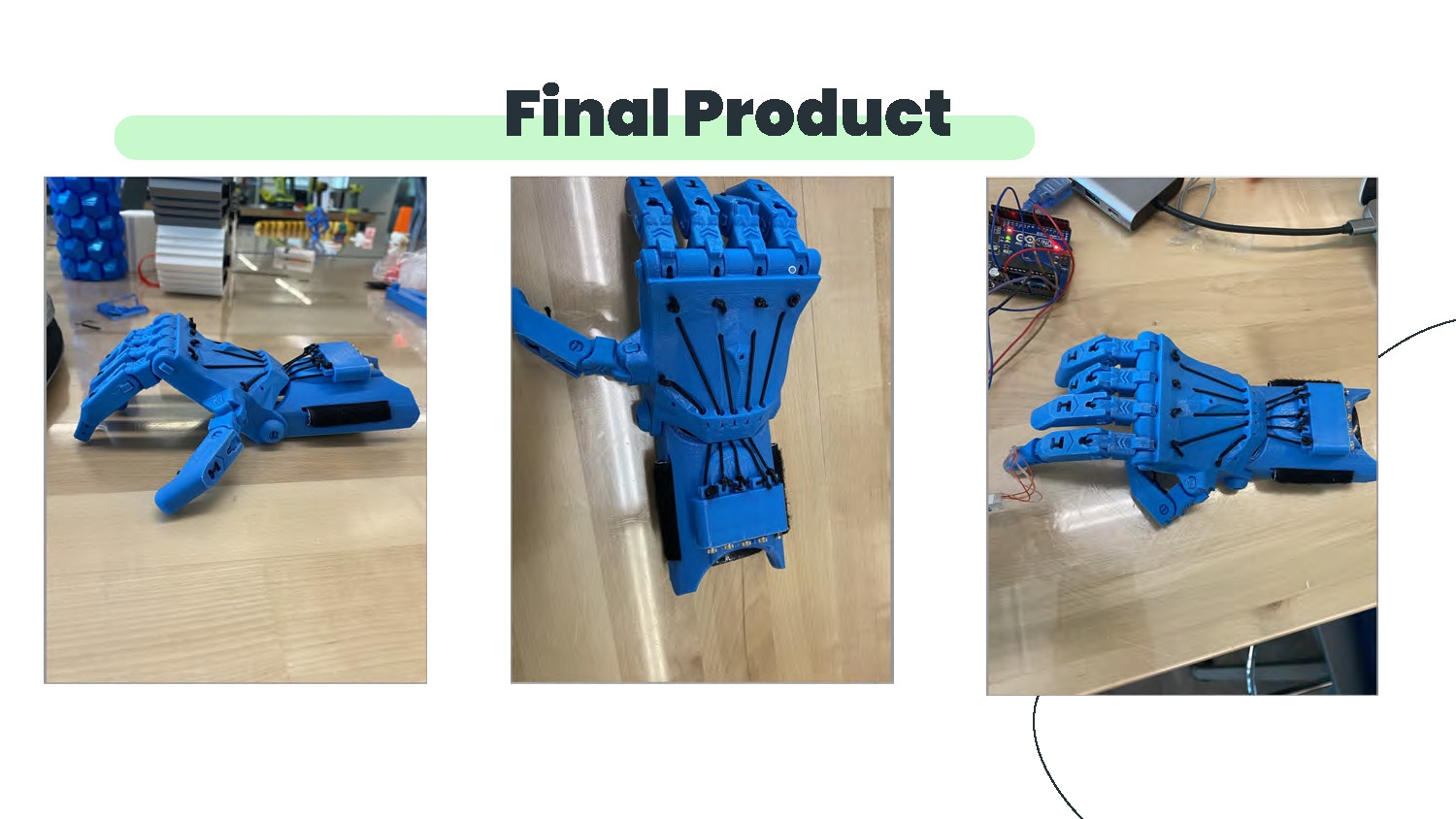

Final Product

Slide-10

Importance of Touch

Give the sensation of feeling to children

Slide-11

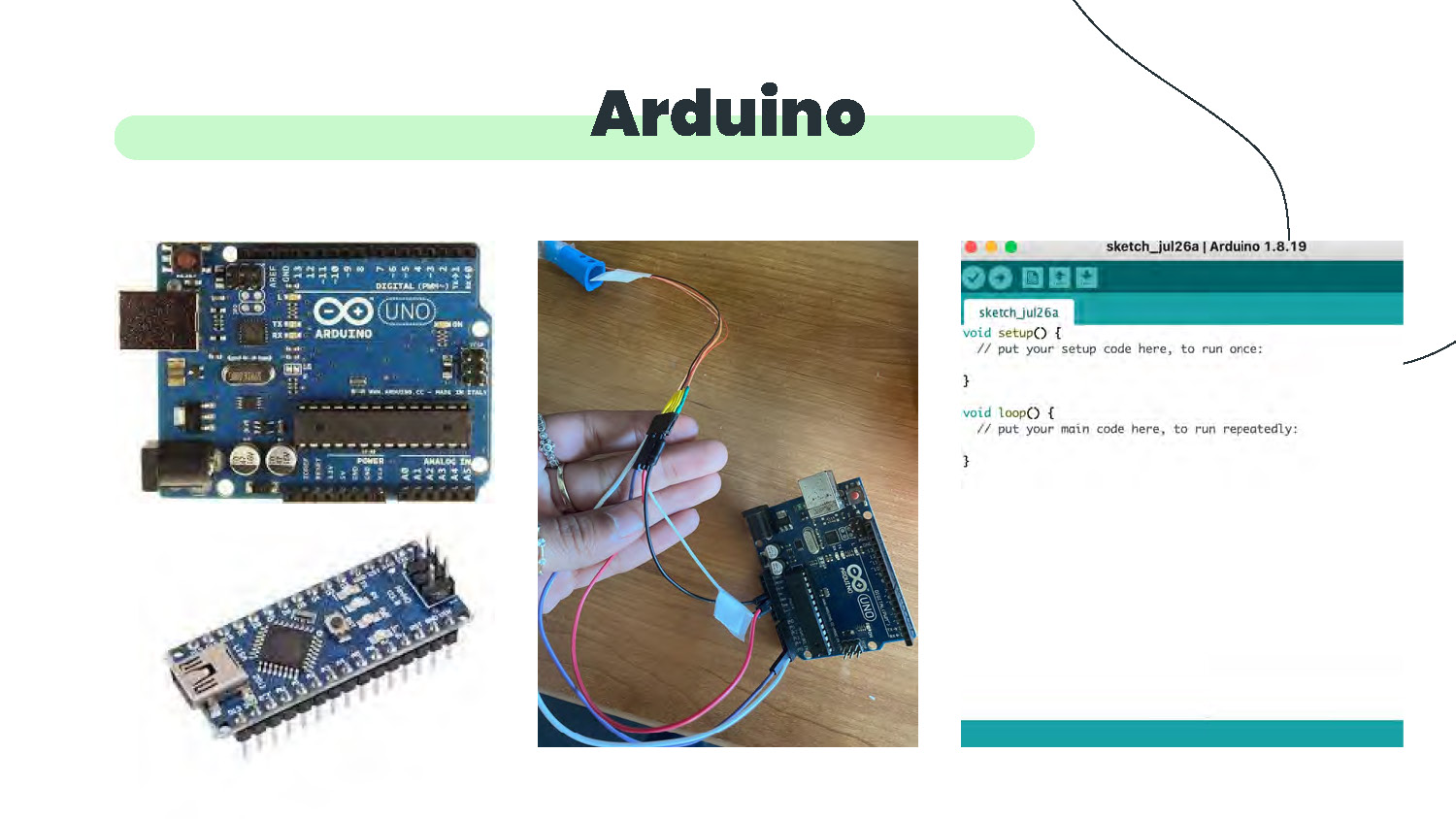

Arduino

- Top-left: a rectangular blue printed circuit board with USB connector on the left, multiple headers along the top and right edges, and white printed markings including the word “UNO.”

- Bottom-left: a smaller blue rectangular circuit board with a micro USB connector at one end and a row of pins along both long edges.

- Center: a photograph of a hand holding several insulated jumper wires and a small black connector; the wires run to a blue circuit board positioned on a wooden surface.

- Right: a screenshot of a software window showing an editor with the text “sketch_jul26a” and two empty functions labeled “void setup() { }” and “void loop() { }”.

Slide-12

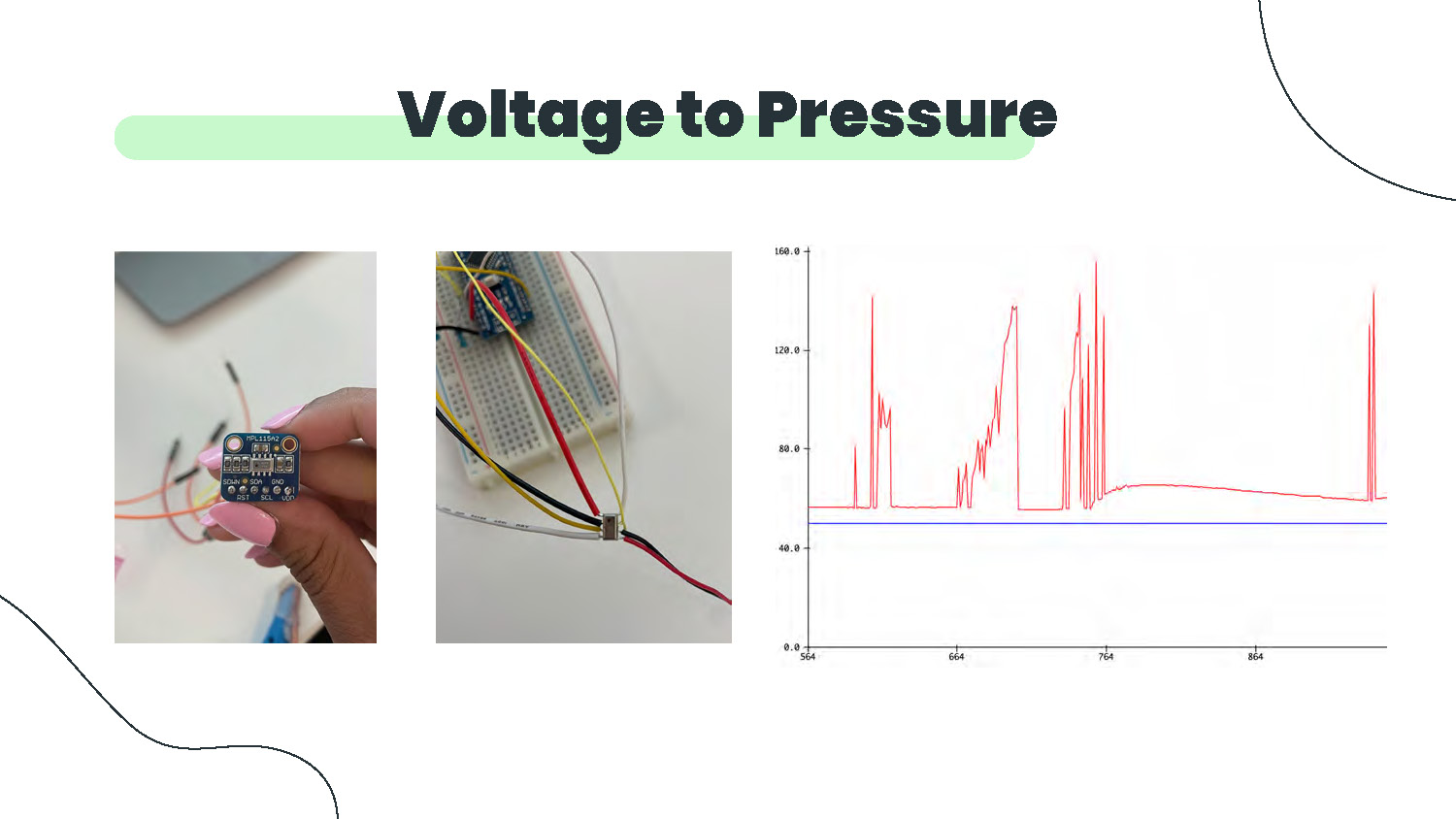

Voltage to Pressure

The image shows three main elements arranged horizontally:

Left photo: A hand holding a small electronic sensor or module with a blue circuit board. The device appears to have multiple pins and components mounted on it. Colored wires (red, yellow, black) are connected to the device.

Center photo: A white breadboard with various colored wires (red, yellow, black, white) inserted into it. The wires appear to be making connections across different rows of the breadboard.

Right graph: A line chart with a red plotted line showing data points. The x-axis appears to span from approximately 554 to 854, while the y-axis ranges from 0 to approximately 160. The line shows several peaks of varying heights, with the highest peaks reaching around 140-150 on the y-axis.

Slide-13

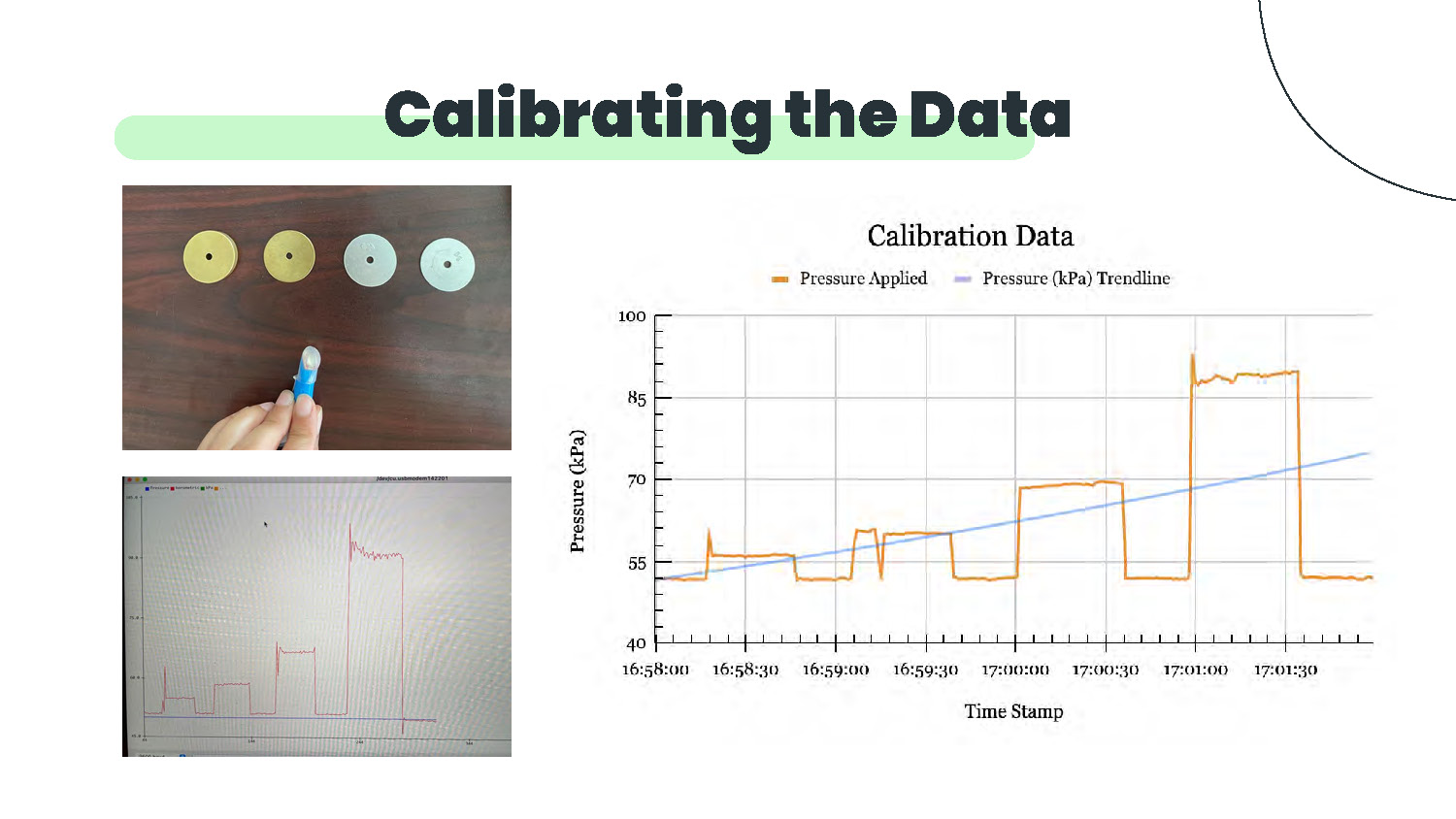

Calibrating the Data

The image shows three main elements:

Top left photo: Four circular discs arranged in a 2x2 grid on a dark wooden surface. Two discs appear yellow/gold colored and two appear light blue/cyan colored. Each disc has a small dark center hole. A hand is visible holding a blue cylindrical object.

Bottom left photo: A computer screen displaying what appears to be a data plotting or graphing software interface. The screen shows a grid with red line plots forming rectangular step patterns at different levels.

Right graph: A chart titled "Calibration Data" with a legend indicating "Pressure Applied" (orange line) and "Pressure (kPa) Trendline" (blue line). The x-axis shows time stamps ranging from approximately 16:58:00 to 17:01:30. The y-axis shows pressure values from 40 to 100 kPa. The orange line shows step-like patterns with plateaus at different pressure levels, while the blue line shows a gradual upward trend.

Slide-14

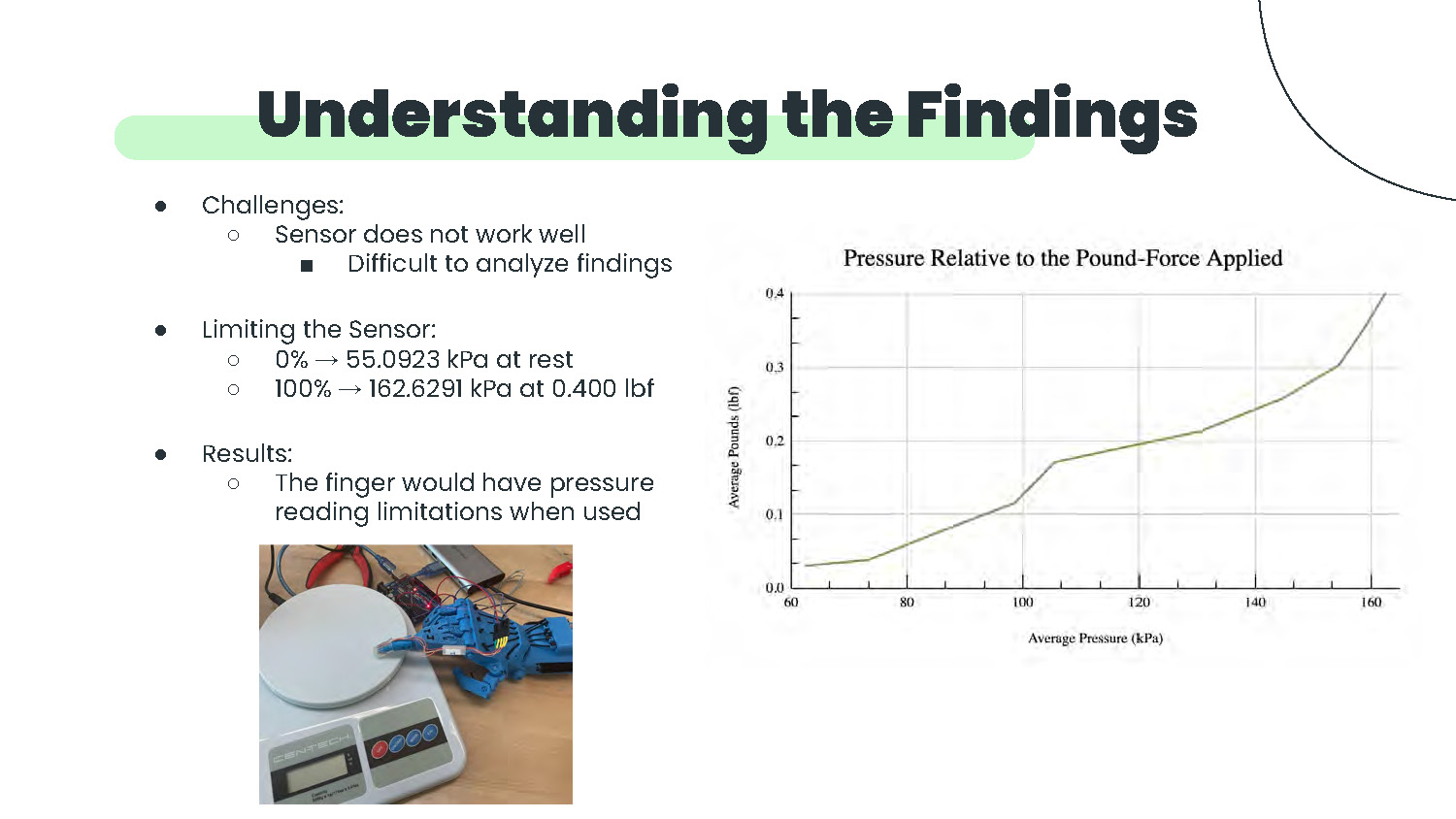

Understanding the Findings

Challenges:

- Sensor does not work well

- Difficult to analyze findings

Limiting the Sensor:

- 0% → 55.0923 kPa at rest

- 100% → 162.6291 kPa at 0.400 lbf

Results:

- The finger would have pressure reading limitations when used

Slide-15

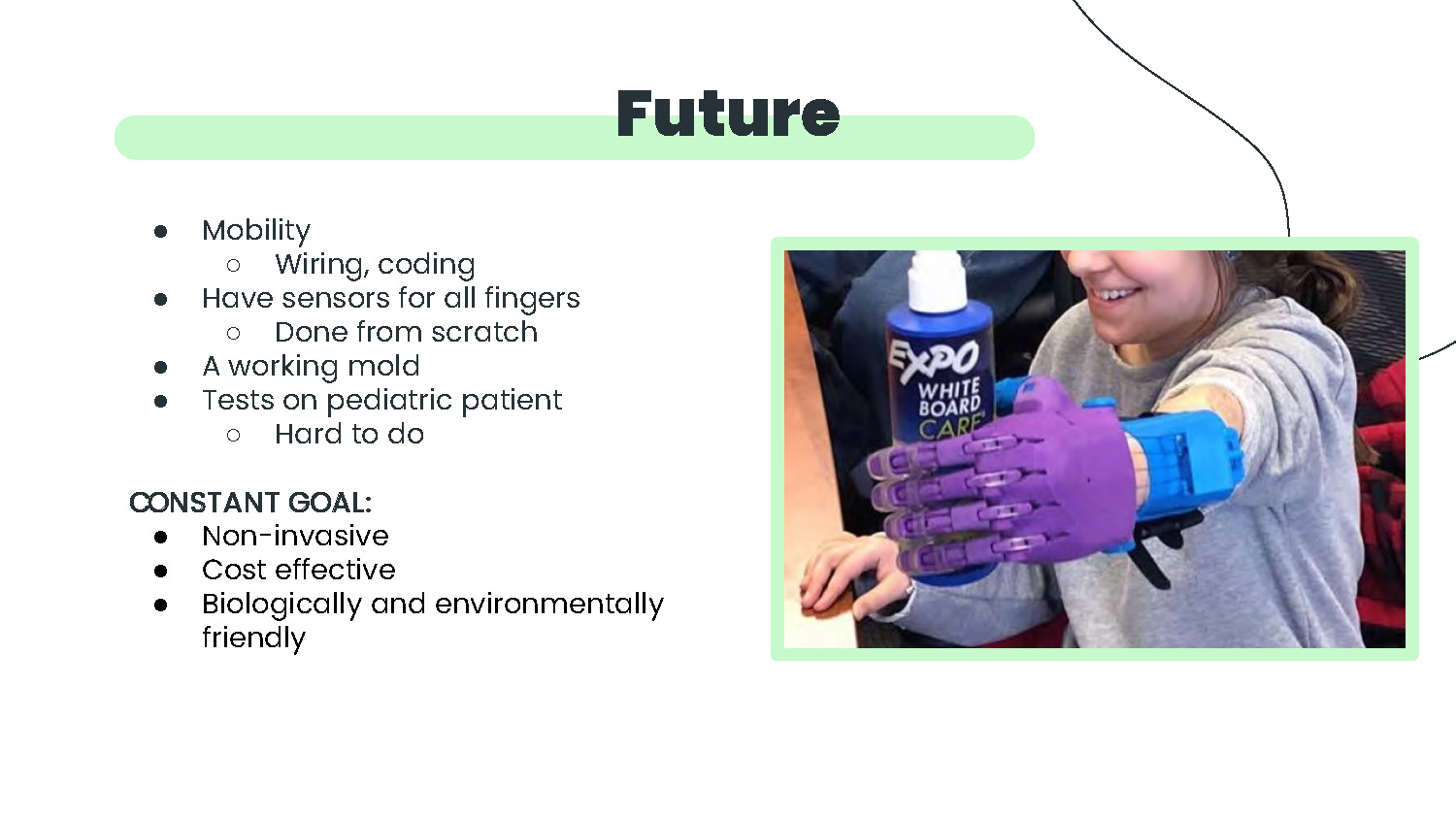

Future

- Mobility

- Wiring, coding

- Have sensors for all fingers

- Done from scratch

- A working mold

- Tests on pediatric patient

- Hard to do

CONSTANT GOAL:

- Non-invasive

- Cost effective

- Biologically and environmentally friendly

Slide-16

References

- https://www.nationwidechildrens.org/family-resources-education/700childrens/2018/04/limb-loss-adapting-to-the-challenges-and-hitting-milestones

- https://cdn.thingiverse.com/assets/09/62/11/29/80/RAPTOR_assembly_instructions_R1.2.pdf

- https://www.3dprintingspot.com/post/petg-vs-pla-main-pros-cons-of-both

- https://media.istockphoto.com/photos/human-and-robotic-hand-touching-picture-id1149086253?k=20&m=1149086253&s=612x612&w=0&h=XciFpCuOAlvMlcJ2ar_yr9-mejm2F9N72p-mSkbcMWo=

- https://www.gmelectronic.com/data/product/1024_1024/pctdetail.774-024.1.jpg

- https://cdn.shoplightspeed.com/shops/642375/files/29464252/800x800x3/arduino-uno-r3-development-board.jpg

- https://mcopro.com/blog/resources/arm-hand-prosthetics/#:~:text=How%20much%20does%20a%20prosthetic,the%20latest%20myoelectric%20arm%20technology.

- https://www.vmcdn.ca/f/files/airdrietoday/import/24/2018/05/GT-20180130-RVW0302-301309985-AR.jpeg

End of Presentation

Click the right arrow to return to the beginning of the slide show.

For a downloadable version of this presentation, email: I-SENSE@FAU.