Inverse Design of Wave Energy Converter Using Artificial Intelligence

Slide-1

Presented by Christopher Snook

REU Mentor: Dr. Yufei Tang

Slide-2

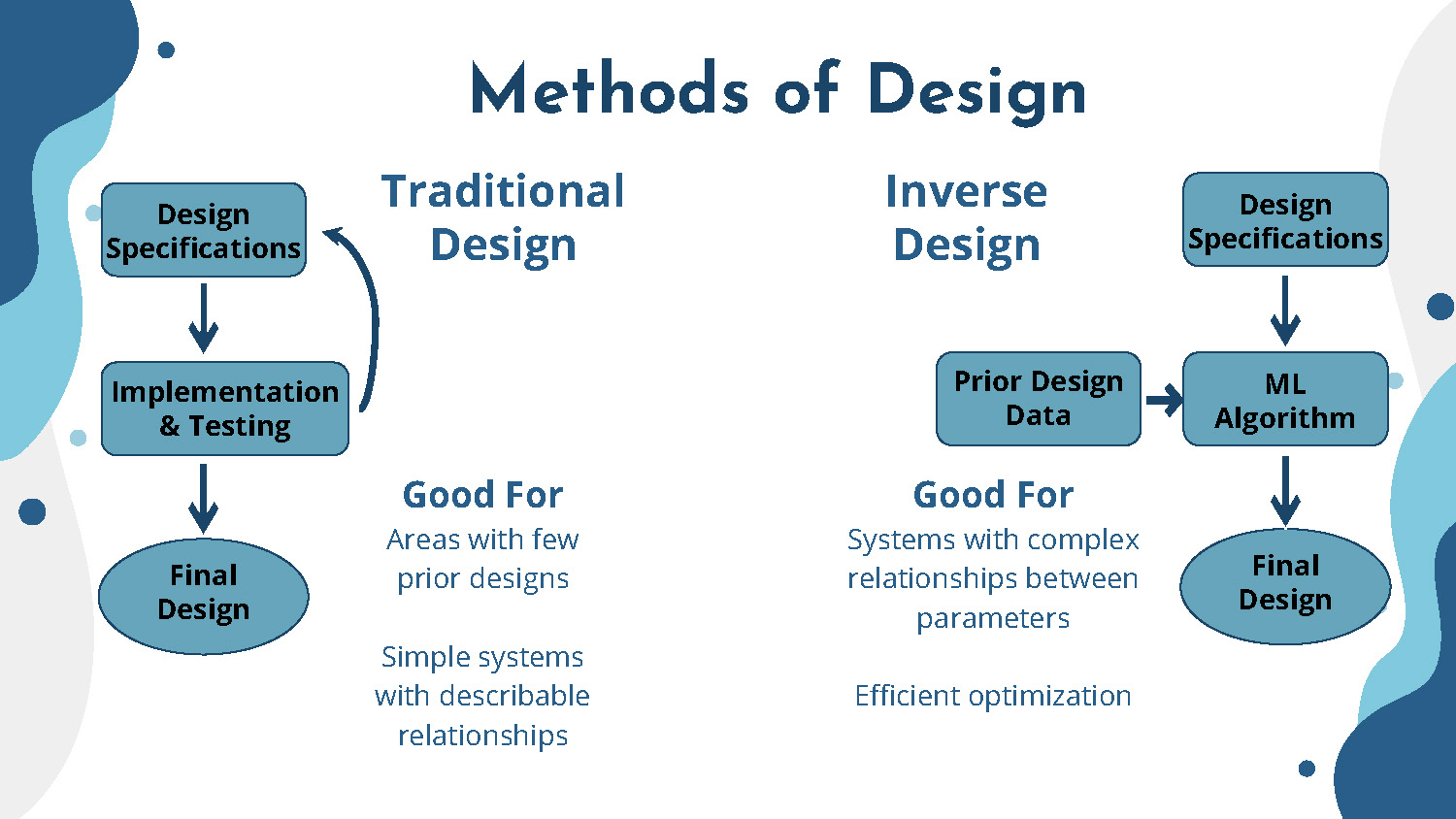

Methods of Design

This slide compares two design methodologies:

Traditional Design

Process: Design Specifications → Implementation & Testing → Final Design

Good For:

- Areas with few prior designs

- Simple systems with describable relationships

Inverse Design

Process: Design Specifications → ML Algorithm → Final Design

Uses Prior Design Data

Good For:

- Systems with complex relationships between parameters

- Efficient optimization

Slide-3

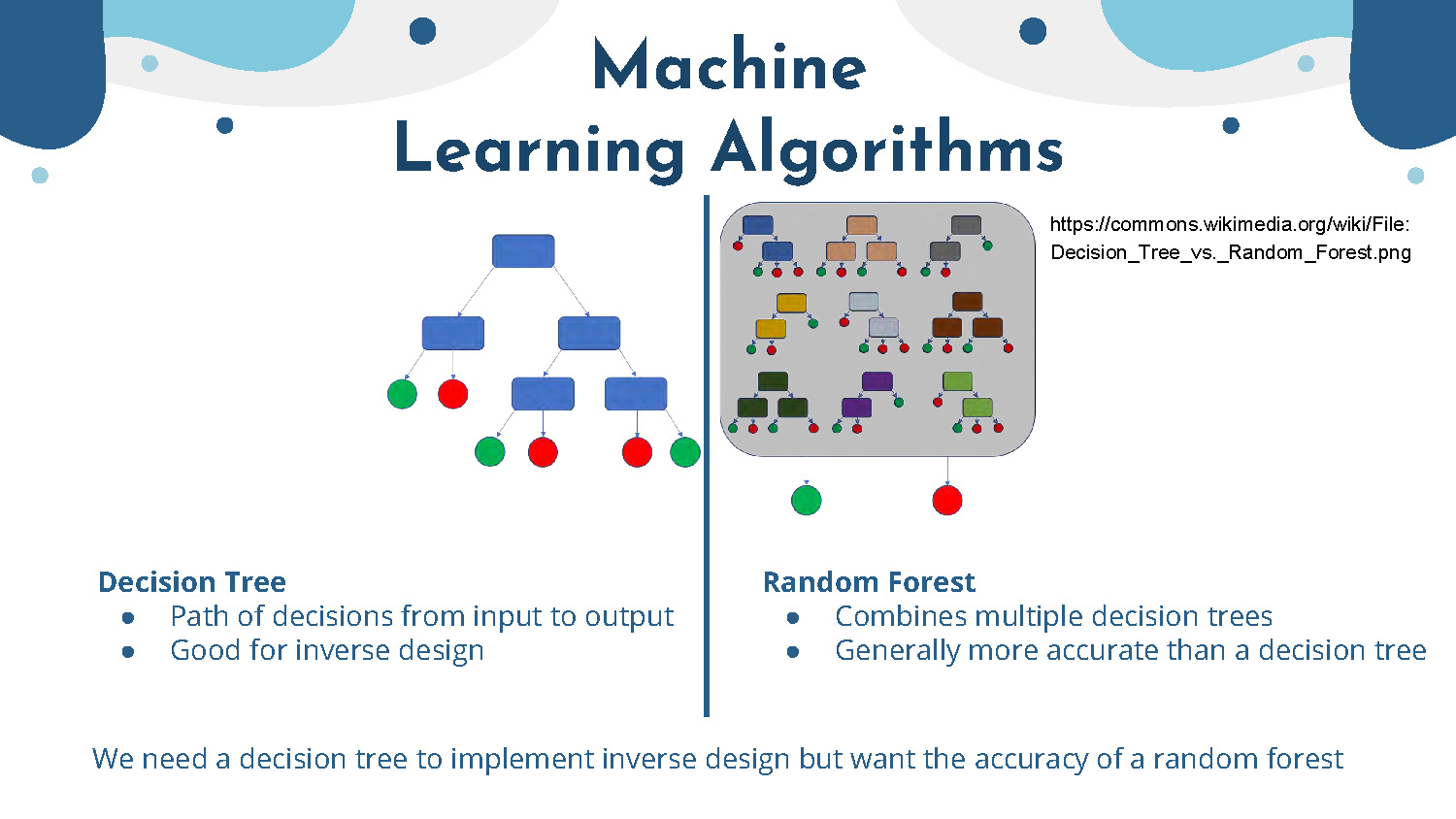

Machine Learning Algorithms

Decision Tree

- Path of decisions from input to output

- Good for inverse design

Random Forest

- Combines multiple decision trees

- Generally more accurate than a decision tree

Challenge: We need a decision tree to implement inverse design but want the accuracy of a random forest

Image reference: Decision Tree vs. Random Forest diagram from Wikimedia Commons

Slide-4

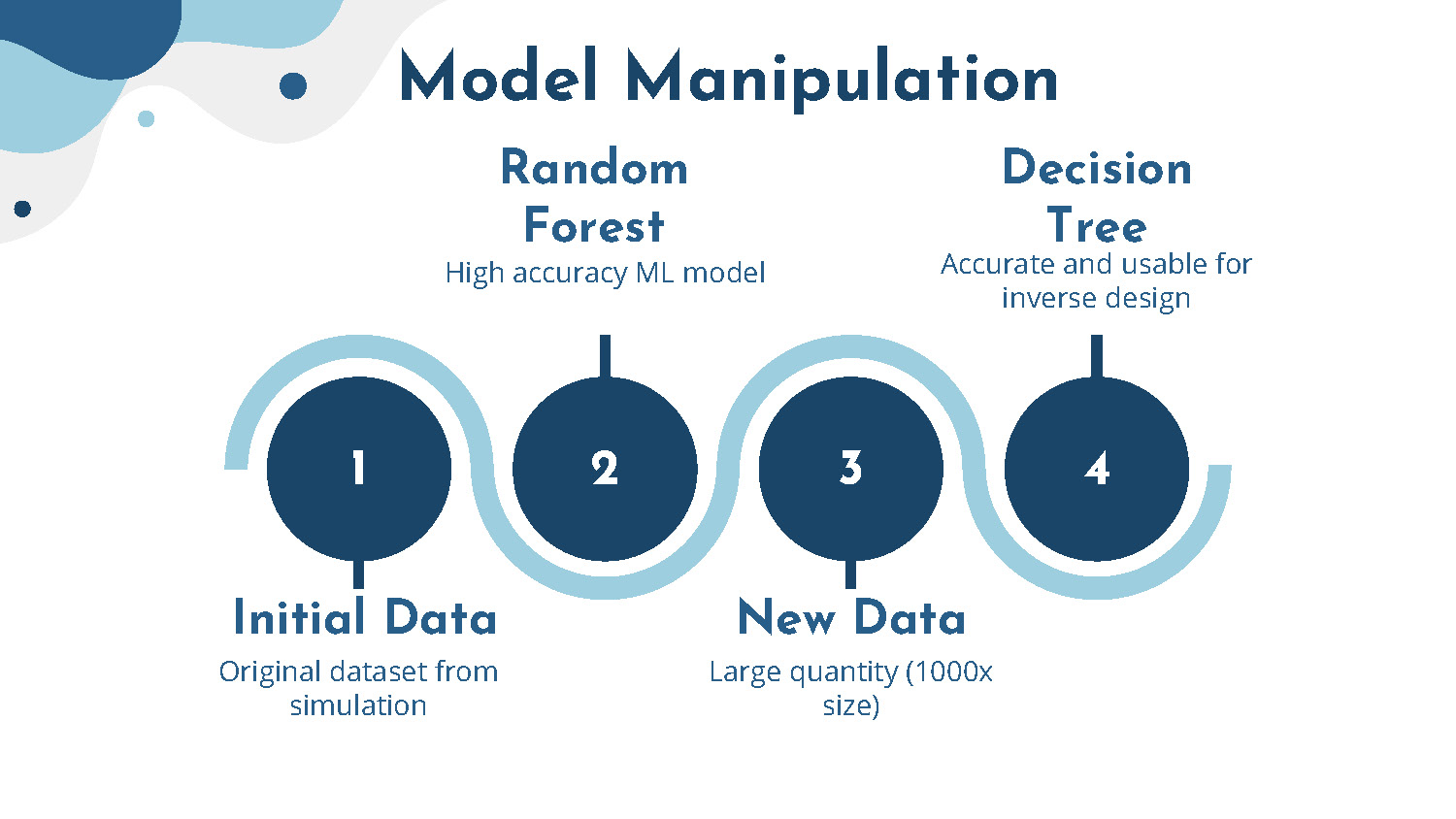

Model Manipulation

The model manipulation process consists of 4 steps:

Step 1 - Initial Data: Original dataset from simulation

Step 2 - Random Forest: High accuracy ML model

Step 3 - New Data: Large quantity (1000x size)

Step 4 - Decision Tree: Accurate and usable for inverse design

Slide-5

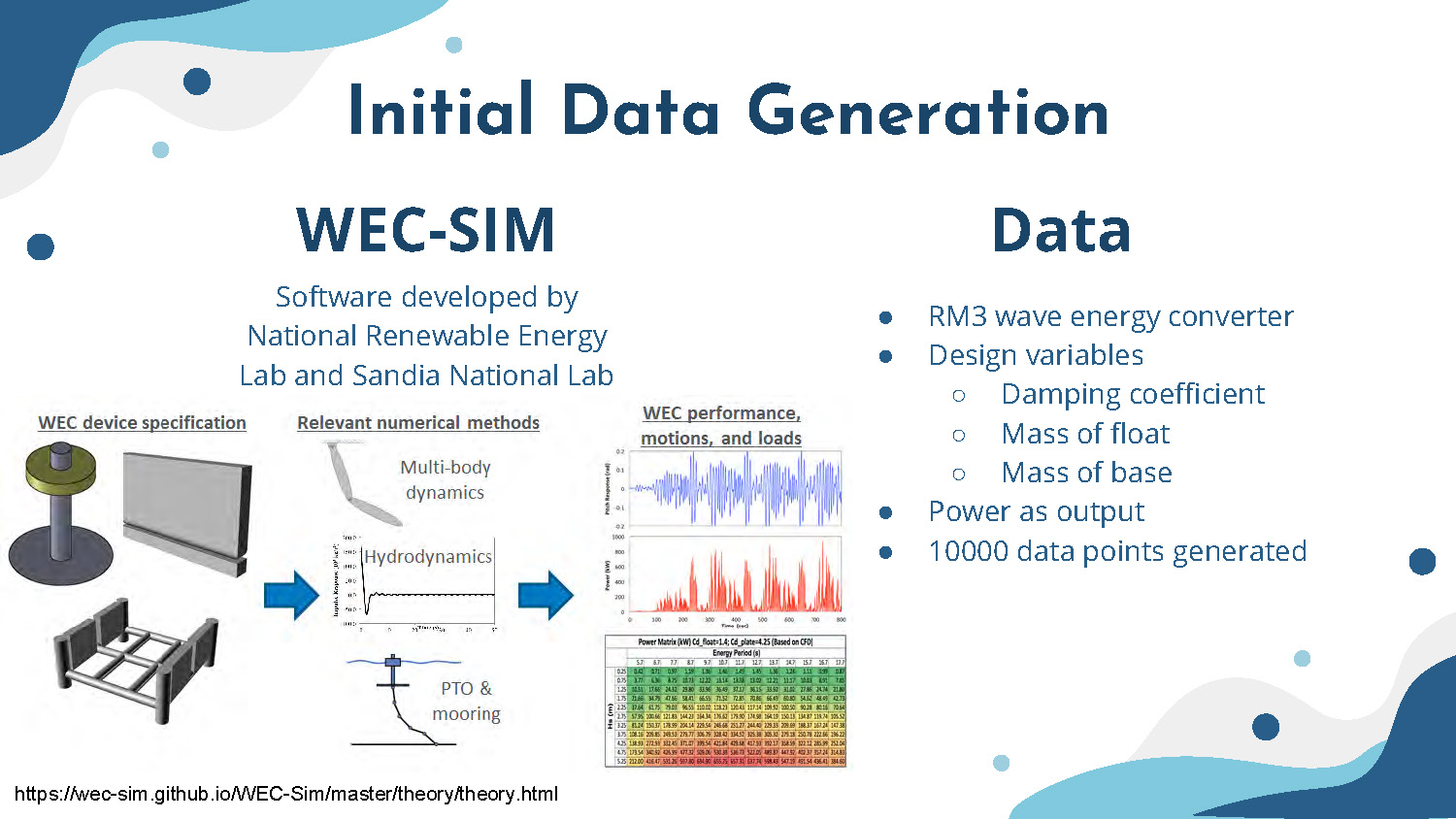

WEC-SIM Initial Data Generation

WEC-SIM is software developed by National Renewable Energy Lab and Sandia National Lab.

Image shows three illustrations of wave energy converter components

Multi-body dynamics

Hydrodynamics

PTO & mooring

Graphs showing performance data and a colored power matrix table

Reference: WEC-Sim theory documentation available at wec-sim.github.io

Data

- RM3 wave energy converter

- Design variables:

- Damping coefficient

- Mass of float

- Mass of base

- Power as output

- 10000 data points generated

Slide-6

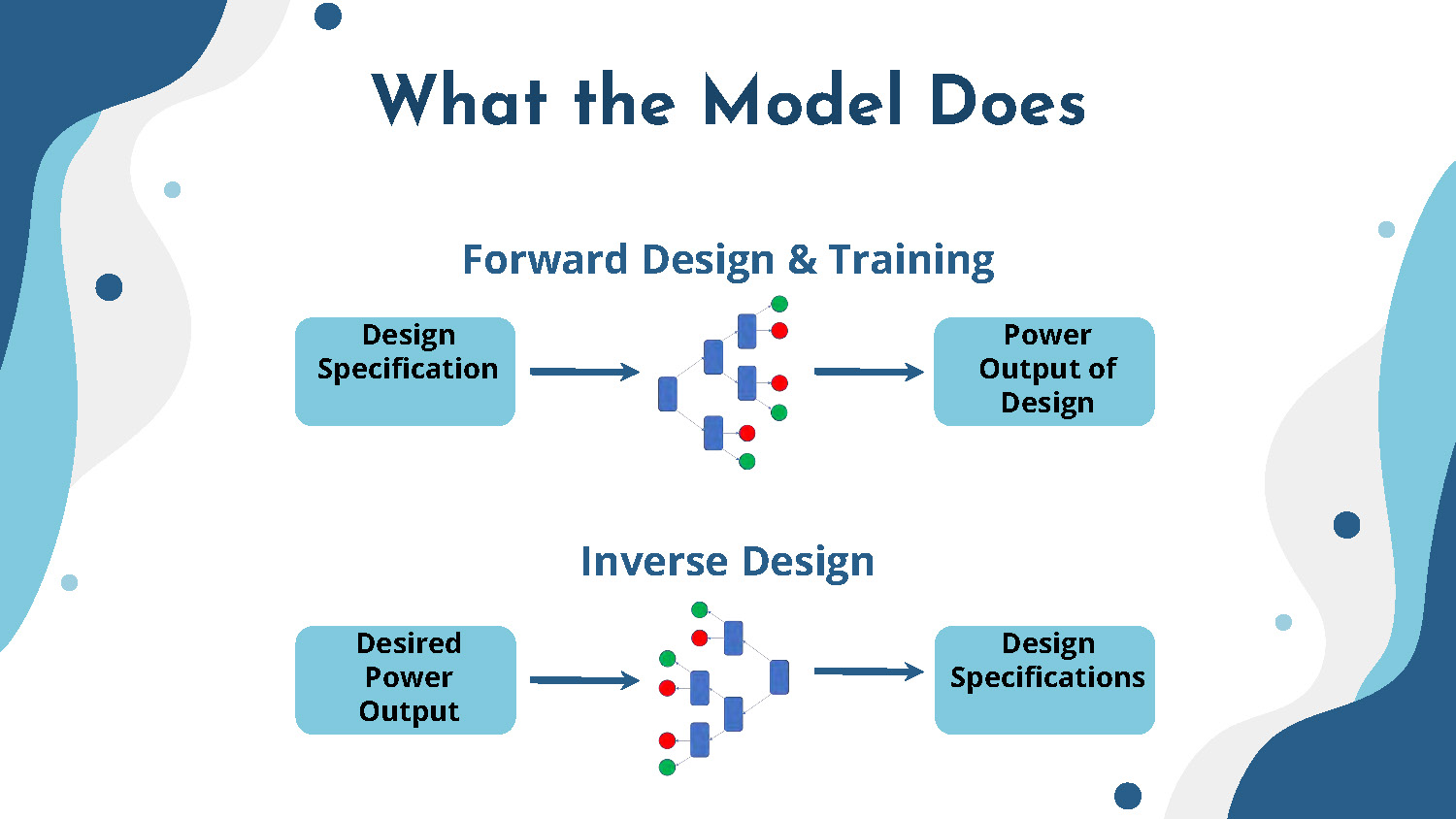

What the Model Does

Forward Design & Training

Design Specifications → Power Output of Design

Inverse Design

Desired Power Output → Design Specification

Slide-7

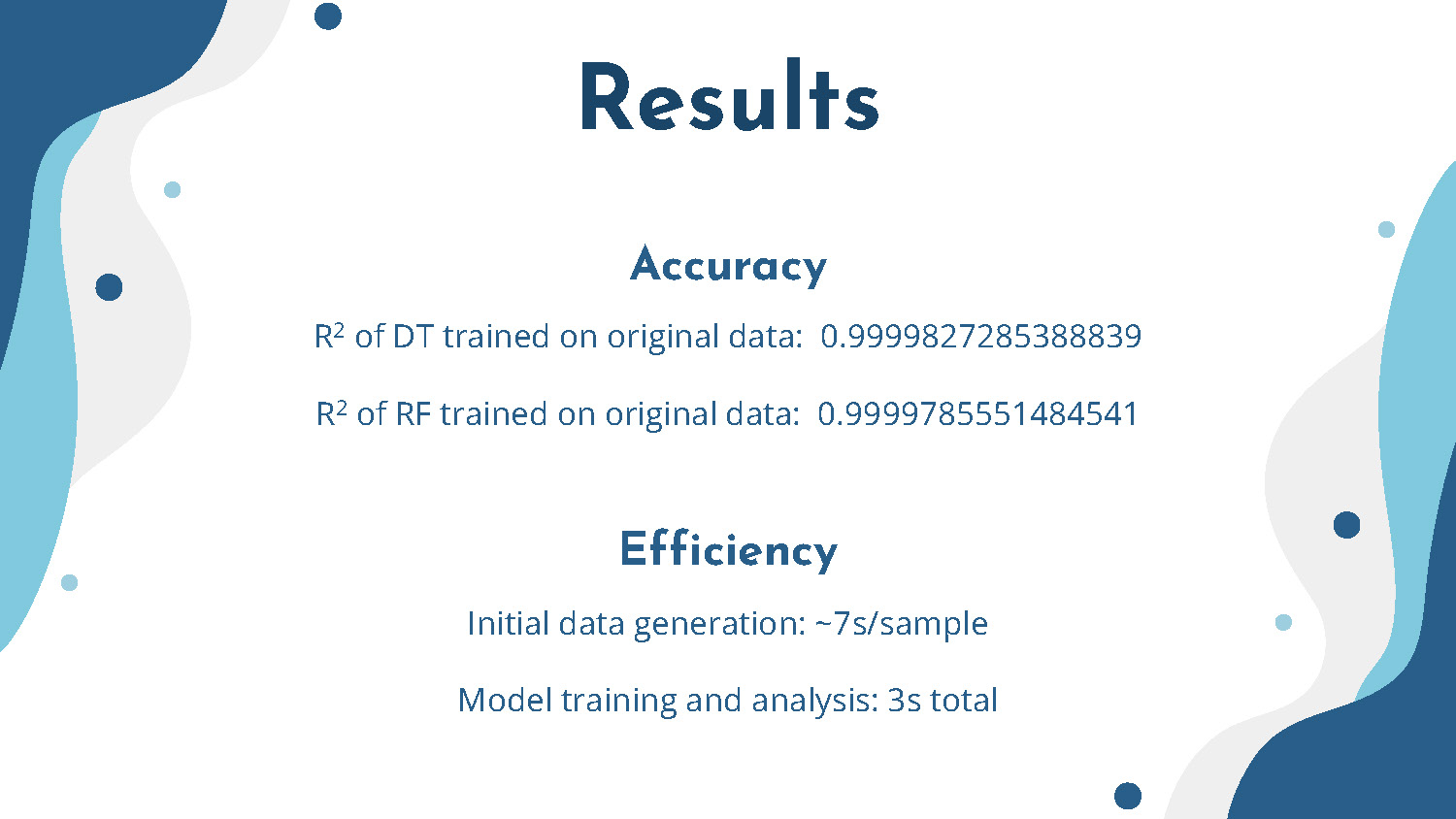

Results

Accuracy

- R² of DT trained on original data: 0.9999827285388839

- R² of RF trained on original data: 0.9999785551484541

Efficiency

- Initial data generation: ~7s/sample

- Model training and analysis: 3s total

Slide-8

Conclusions

Was this practical?

- Inverse design worked

- Actual results were limited due to data

What next?

- More Data

- More complex systems

- Optimize ML algorithm

End of Presentation

Click the right arrow to return to the beginning of the slide show.

For a downloadable version of this presentation, email: I-SENSE@FAU.