Marine Hydrokinetic Turbine Optimization through Control Co-Design

Slide-1

Presenter: Austin Snyder

Advisors: Dr. Yufei Tang, Arezoo Hasankhani

Slide-2

Marine Hydrokinetic Turbines

Advantages

- Renewable

- "Clean"

- Consistent

Challenges

- Cost of Components

- Complex Environment

Image of "KAIRYU" Ocean Current Turbine System

Slide-3

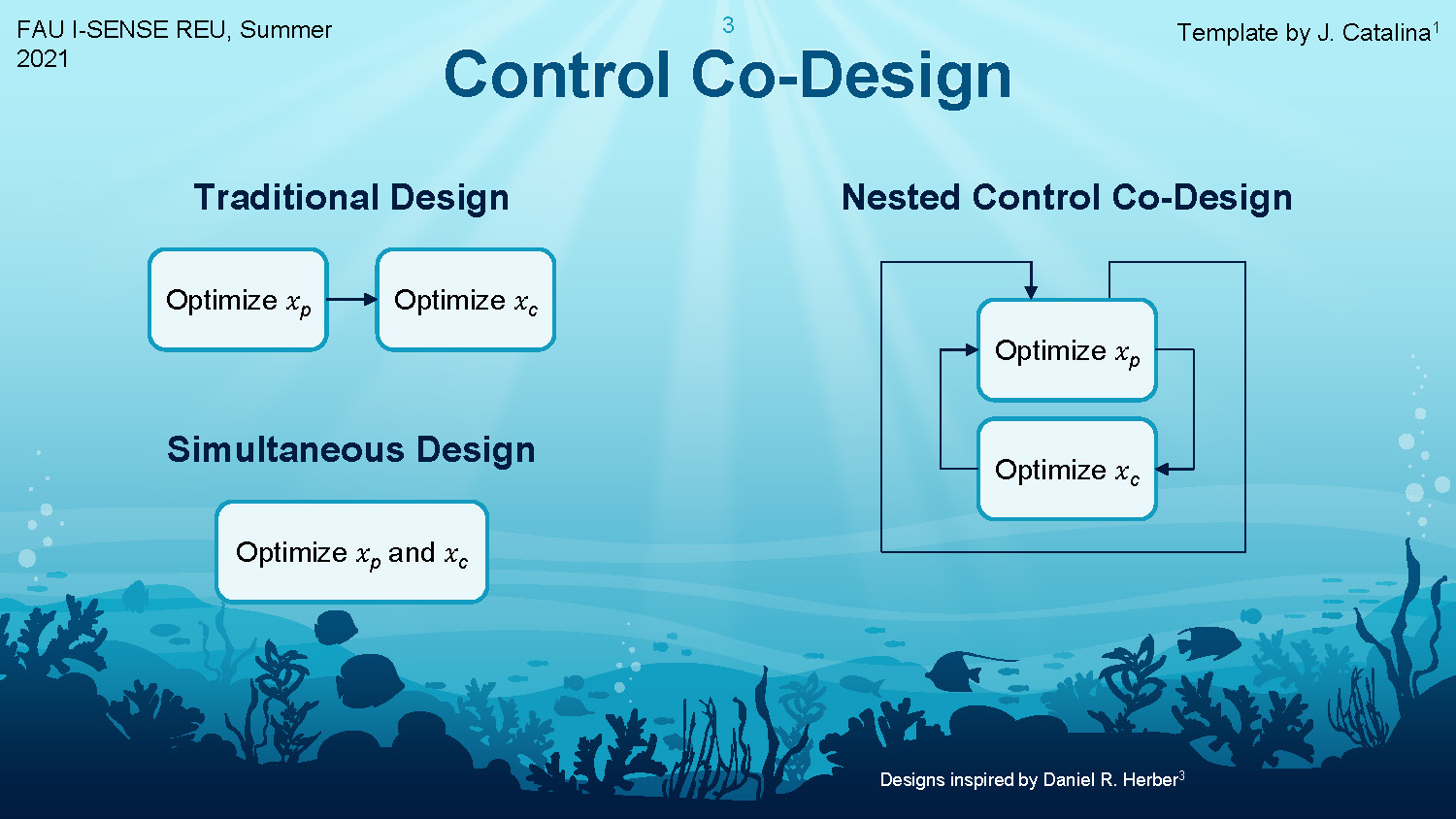

Control Co-Design

Three optimization approaches are shown in flowchart format:

Traditional Design

Sequential process: Optimize xp, then Optimize xc

Nested Control Co-Design

Nested process: Optimize xc, then Optimize xp

Simultaneous Design

Concurrent process: Optimize xp and xc simultaneously

Designs inspired by Daniel R. Herber

Slide-4

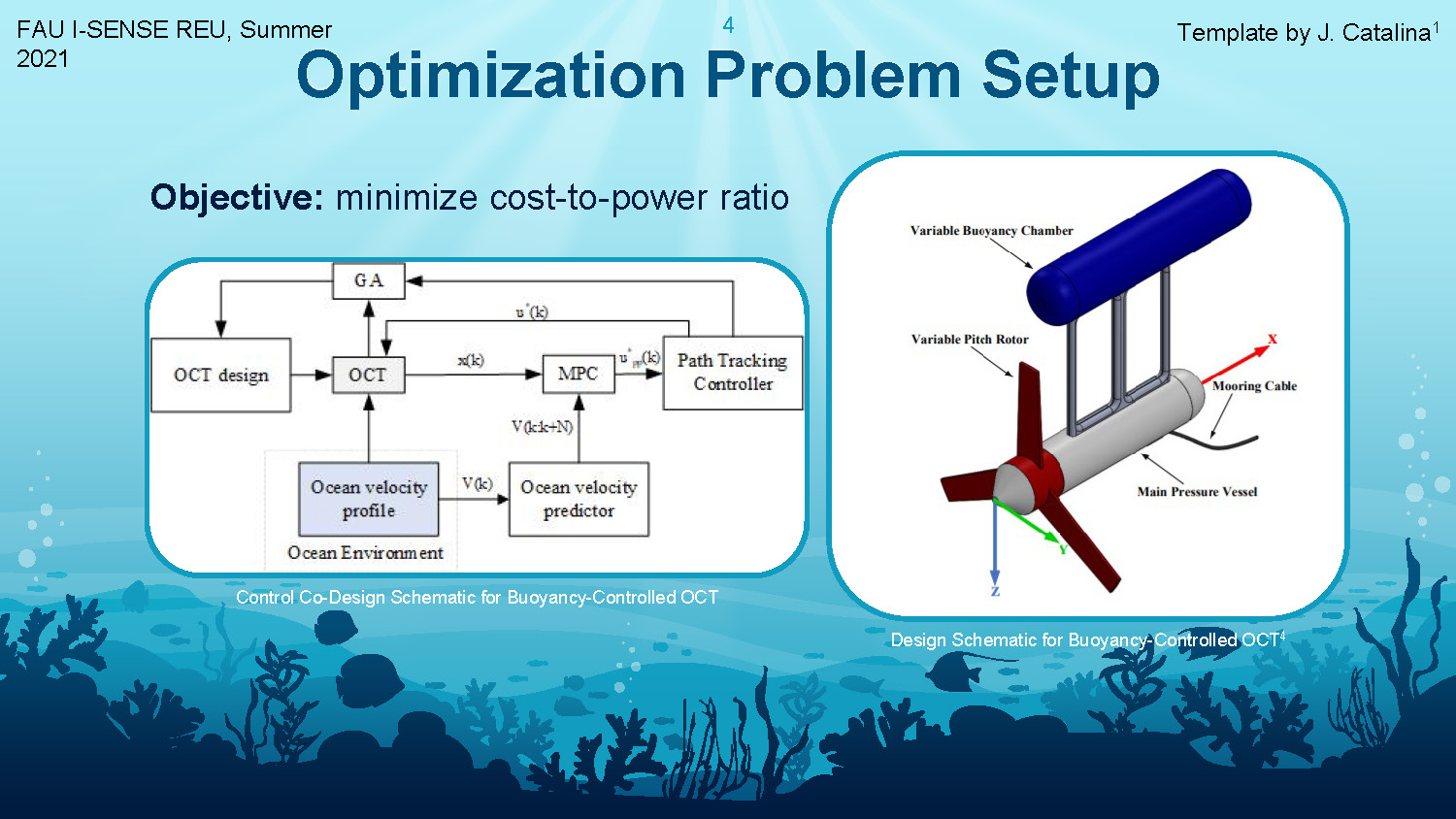

Optimization Problem Setup

Objective: minimize cost-to-power ratio

Control Co-Design Schematic for Buoyancy-Controlled OCT

System control diagram illustrating the control co-design approach for the buoyancy-controlled ocean current turbine.

Design Schematic for Buoyancy-Controlled OCT

Technical diagram showing the ocean current turbine design with buoyancy control system.

Slide-5

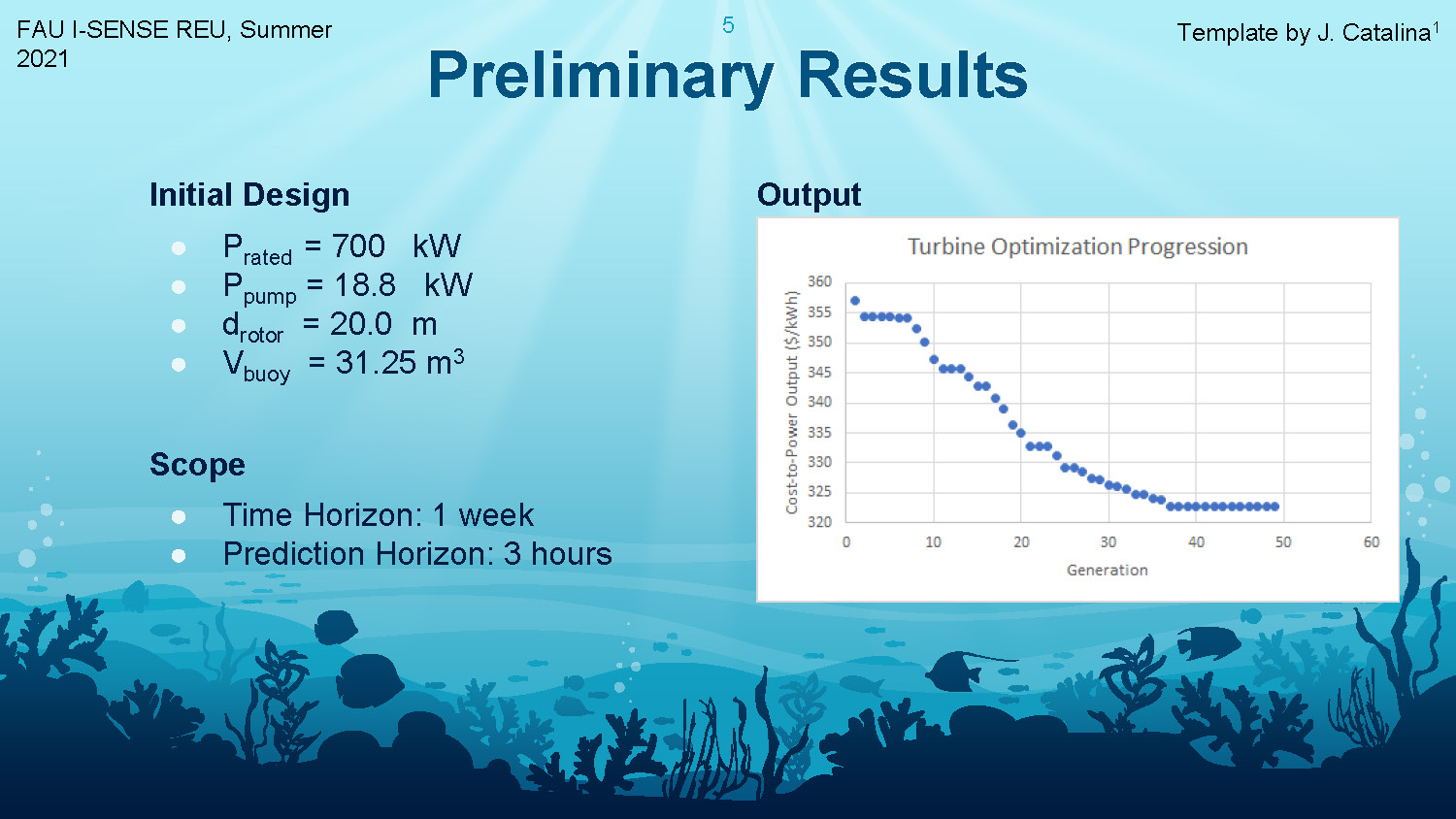

Preliminary Results

Initial Design

- Prated = 700 kW

- Ppump = 18.8 kW

- drotor = 20.0 m

- Vbuoy = 31.25 m3

Scope

- Time Horizon: 1 week

- Prediction Horizon: 3 hours

Output

Graph showing optimization results and performance metrics over time.

Slide-6

Conclusions & Next Steps

Future Plans

- ACC Paper Submission

- Generalized Application

Ongoing Work

- Reduce Time Complexity

- Linear Model Approximations

- Standardize Cost & Weight

Image: ACC 2022 Logo

Slide-7

References

[1] Catalina, J. (n.d.). Blue Ocean. Slides Carnival; Piensa en Pixels. https://www.slidescarnival.com/thaisa-free-presentation-template/10437

[2] Dodo, Y., et al. (2019). Development and Design of a Floating Type Ocean Current Turbine System. Practical Design of Ships and Other Floating Structures, 732–755. https://doi.org/https://doi.org/10.1007/978-981-15-4680-8_49

[3] Herber, D. R. Control Co-design Direct Transcription Solution Strategies: Overview and Challenges [PowerPoint slides]. Department of Systems Engineering, Colorado State University. https://www.engr.colostate.edu/~drherber/files/IDADS-Herber.pdf

[4] Hasankani, A., et al. (Unpublished). Modeling and Numerical Simulation of a Buoyancy Controlled Ocean Current Turbine

[5] American Control Conference (2022). [American Control Conference 2022 Logo]. Retrieved from https://acc2022.a2c2.org/

End of Presentation

Click the right arrow to return to the beginning of the slide show.

For a downloadable version of this presentation, email: I-SENSE@FAU.