Conformable 3D Printed Prosthetic Socket for Haptic Feedback Integration

Slide-1

Wen-Yu (Marty) Cheng, Chad Coarsey, M.S., and Professor Eric Engeberg, Ph.D.

Slide-2

Wen-Yu (Marty) Cheng

- FAU Freshman

- Mechanical Engineer

Slide-3

The Motivation

Slide-4

- iLimb Quantum: Hand only $30,000; Full arm $80,000–$120,000

- Open Bionics Hero Arm: Full arm ~$7,000; 3D Printed Components; UK NHS Clinical Trial

- Limbitless Solutions Arm: Full arm $350; 3D Printed Components; US Clinical Trial (UCF-OHSU)

Slide-5

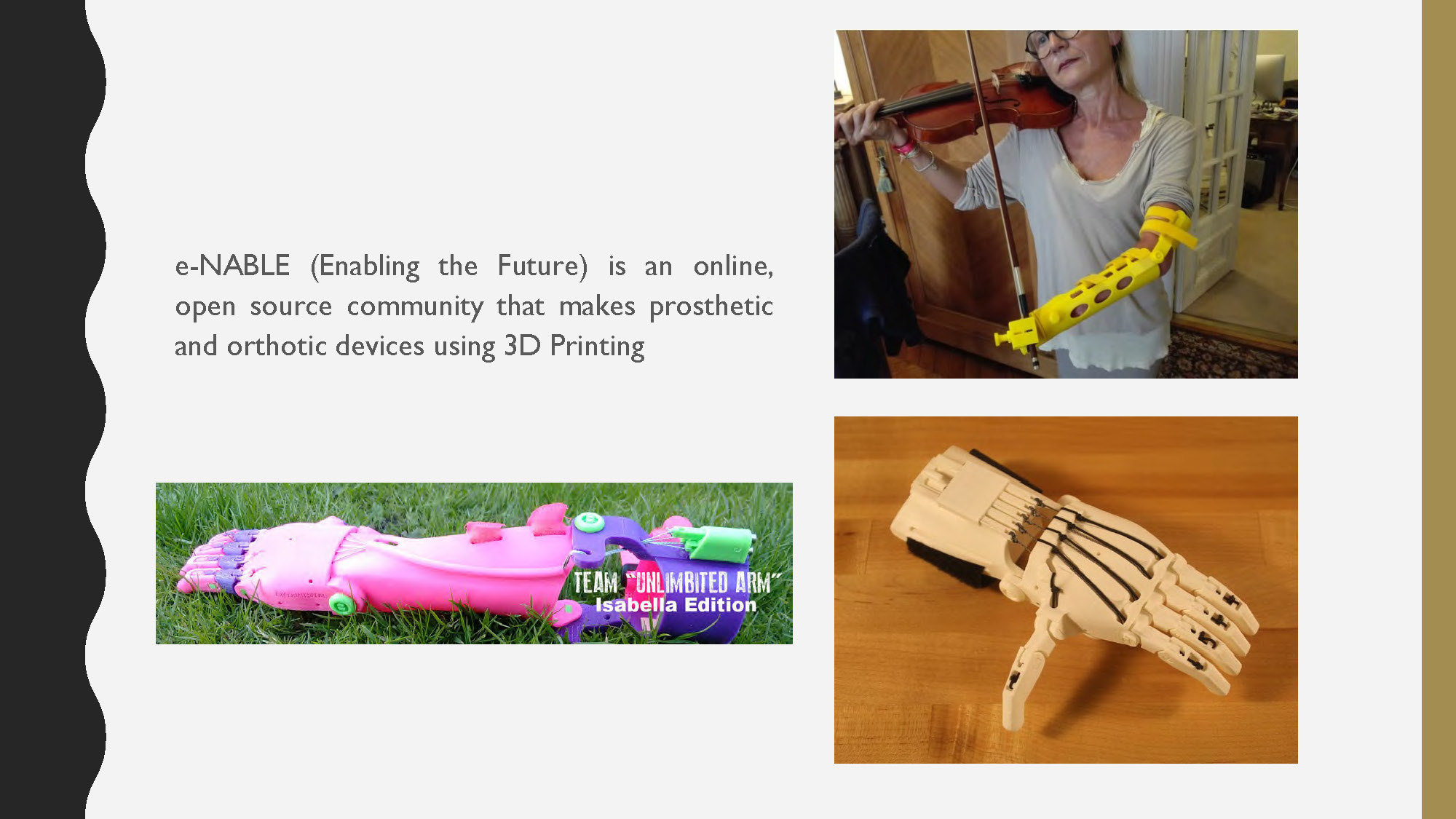

e-NABLE is an open source community making prosthetic and orthotic devices with 3D Printing.

Slide-6

Image of Marty Cheng in office/lab setting

Slide-7

RESEARCH

Slide-8

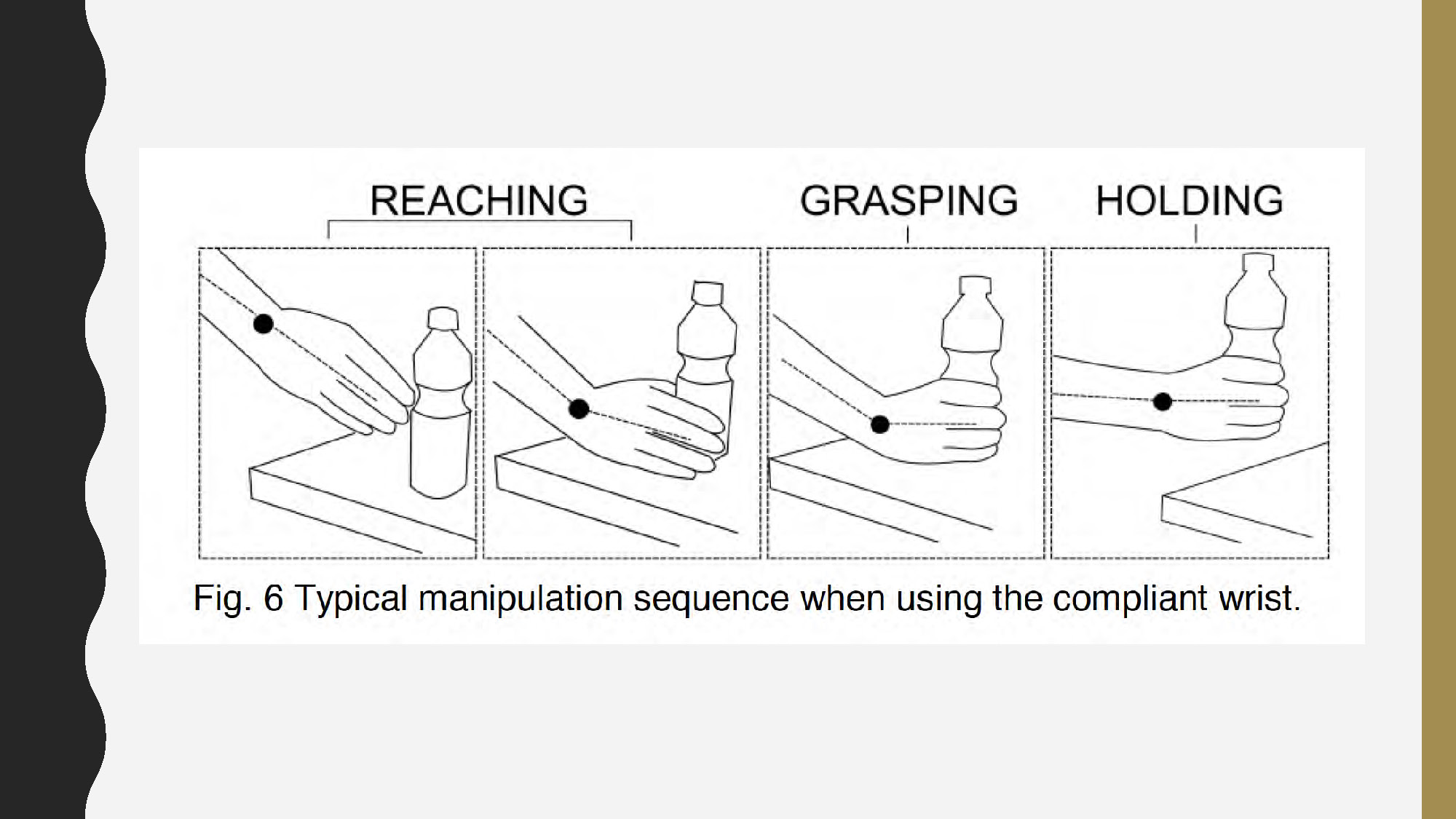

The image is a black and white illustration labeled "Fig. 6 Typical manipulation sequence when using the compliant wrist." It shows a sequence of three actions: REACHING, GRASPING, and HOLDING, depicted from left to right. A hand is shown interacting with a bottle on a flat surface. In the first panel, "REACHING," a hand extends toward a bottle. In the second panel, "GRASPING," the hand's fingers are wrapped around the bottle. In the third panel, "HOLDING," the hand is shown gripping the bottle firmly. A single black dot is visible on the hand in each panel, and dotted lines are used to indicate movement and position.

Slide-9

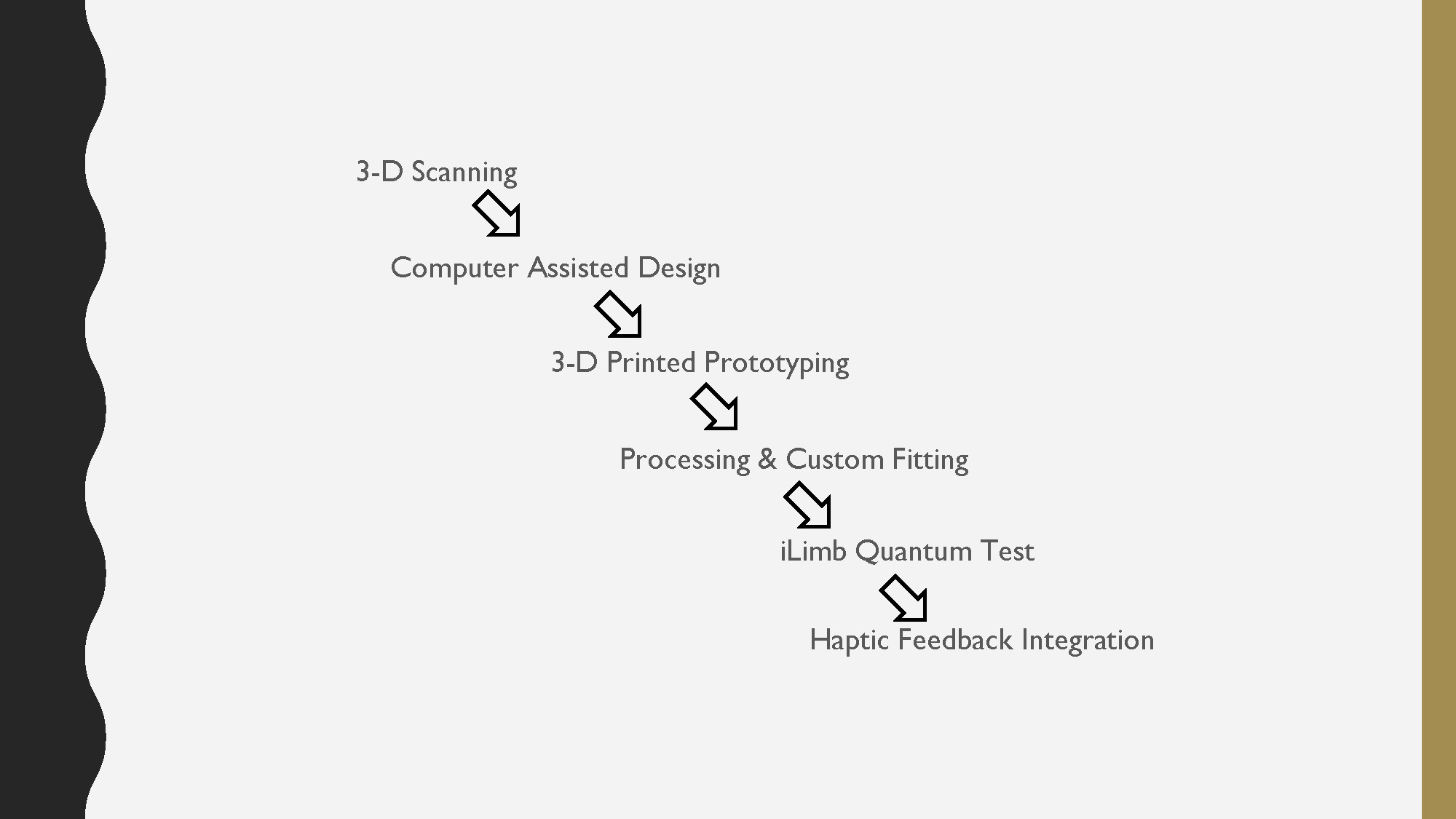

- 3-D Scanning

- Computer Assisted Design

- 3-D Printed Prototyping

- Processing & Custom Fitting

- iLimb Quantum Test

- Haptic Feedback Integration

Slide-10

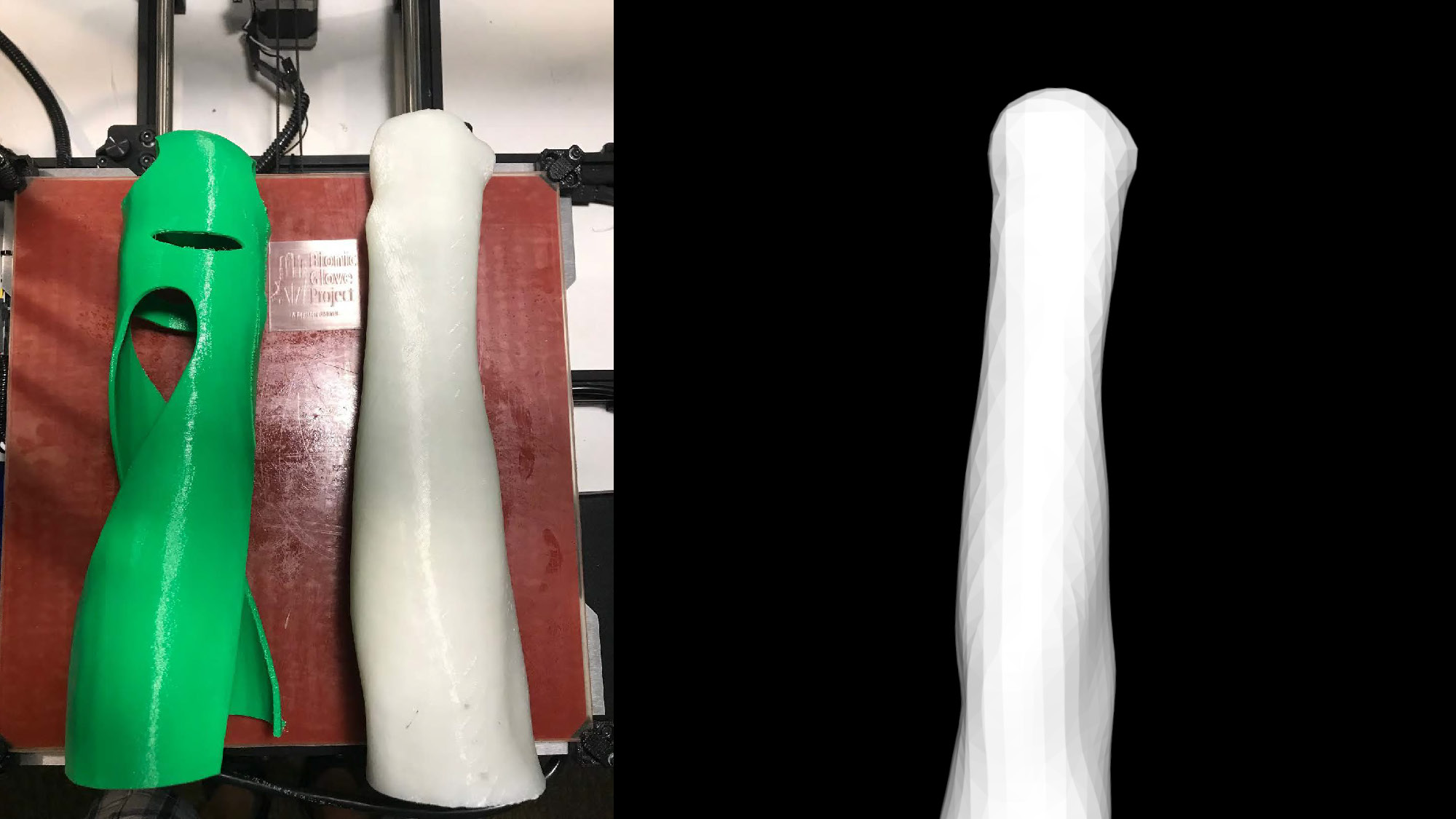

Two side-by-side images on a white surface. The left image shows two physical objects: a tall, green, hollow object with a cutout and a shorter, solid, white object. The right image is a 3D render of a solid white, anatomical model of a human forearm and hand on a black background.

Slide-11

A close-up shot of a 3D printer with its clear door closed. The printer is a Delta-style model, and a tall, green, hollow object is being printed inside. The green object has a slightly irregular shape, and it's being constructed layer by layer by the printer's extruder.

Slide-12

Two side-by-side images of a person with an orange and black brace-like device strapped to their right forearm. The device is connected with green string and the person is holding their right forearm bent. The left image shows the person making a dynamic expression, while the right image shows a more static pose.

Slide-13

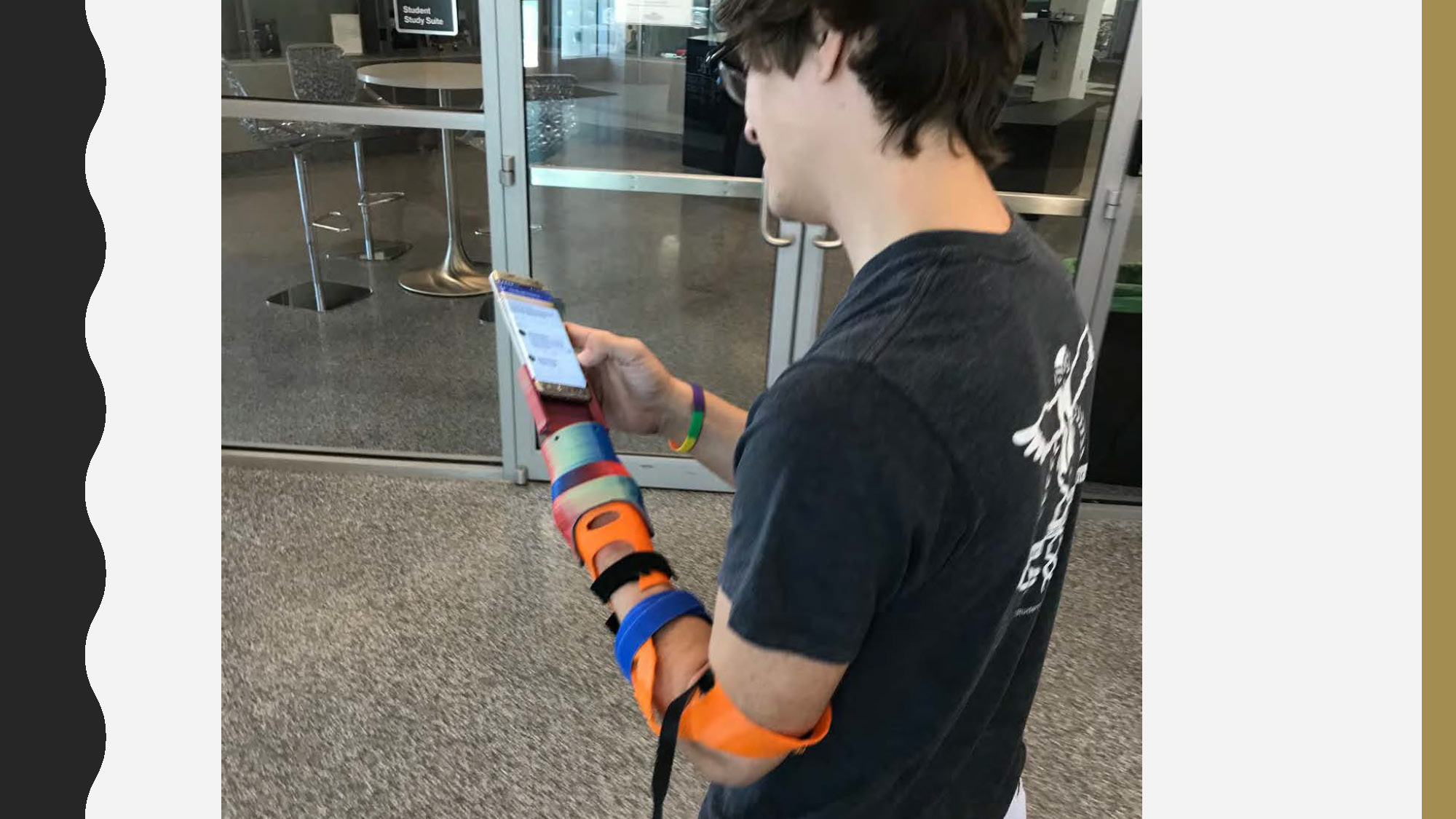

A side view of a person standing indoors, looking down at their cell phone. They are wearing a device composed of multiple colorful, segmented pieces of material strapped to their right forearm with orange straps and black elastic bands. The device has a black rectangular component on the back of the forearm.

Slide-14

A 3D render of a white, hollow, anatomical model of a human forearm and hand, seen from a high angle against a black background. The model has several cutouts and openings along its length.

Slide-15

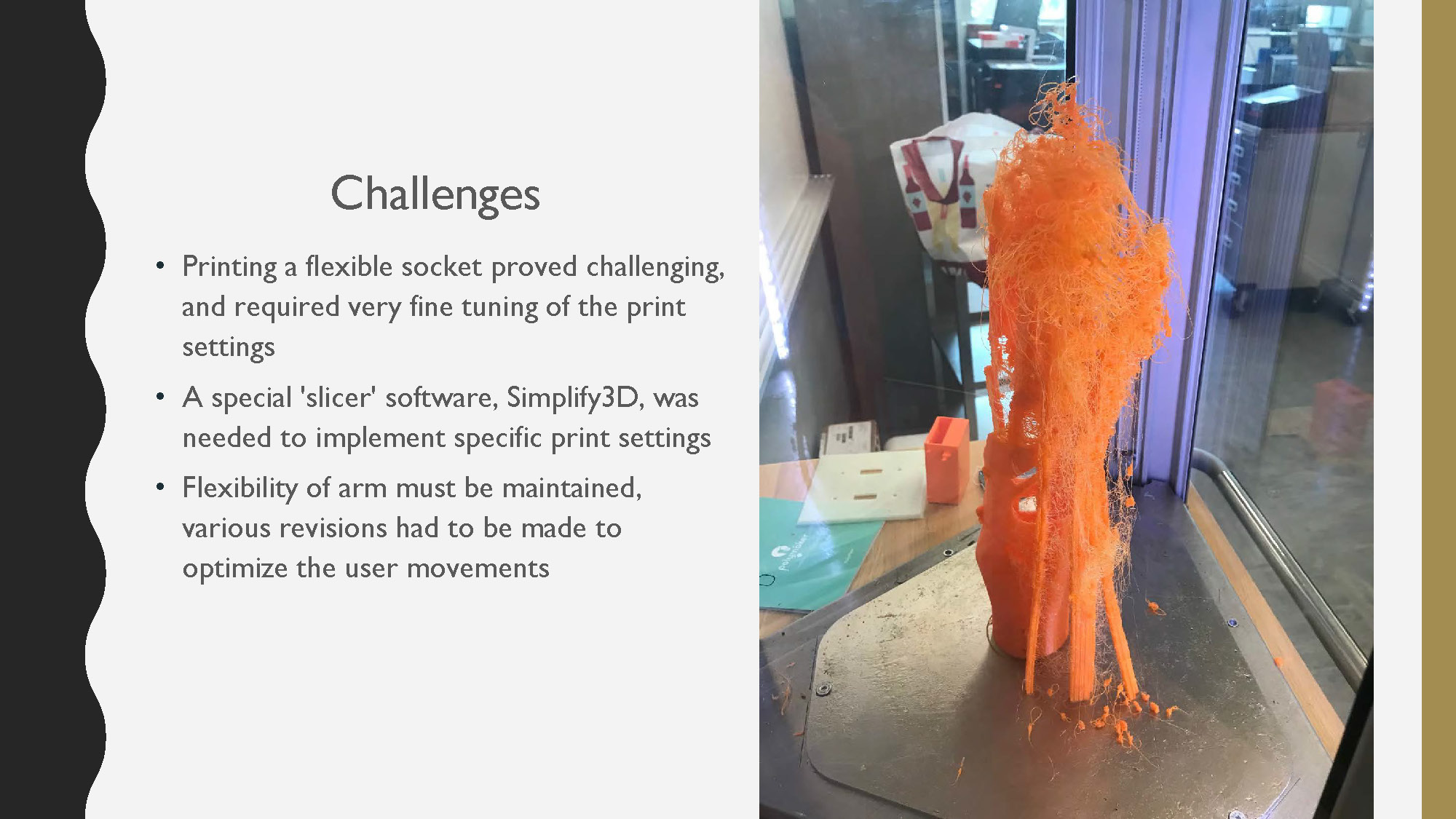

Challenges

- Printing flexible socket required fine-tuned print settings

- Needed slicer software (Simplify3D) for specific settings

- Flexibility of arm must be maintained; revisions required to optimize movement

Slide-17

Two side-by-side images of a man. In the left image, the man smiles while holding a white and blue forearm prosthetic. The prosthetic has an oval-shaped button on the side. In the right image, the same man holds a similar prosthetic against his right arm as if preparing to wear it.

Slide-17

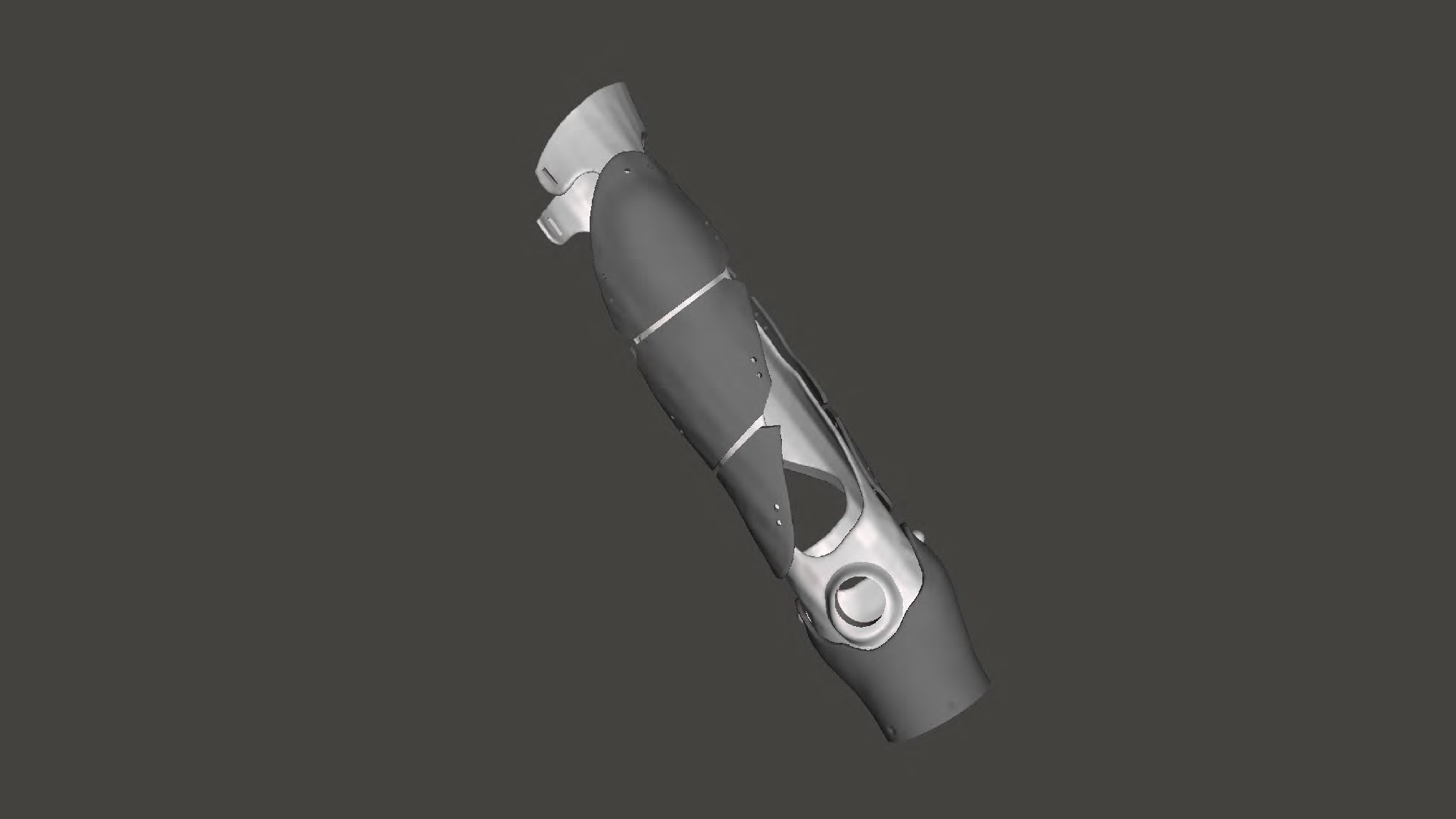

A 3D render of a two-tone prosthetic device for a human forearm, angled against a gray background. The device appears to be composed of interlocking segments in dark gray and a lighter metallic gray, with a circular cutout on the side.

Slide-18

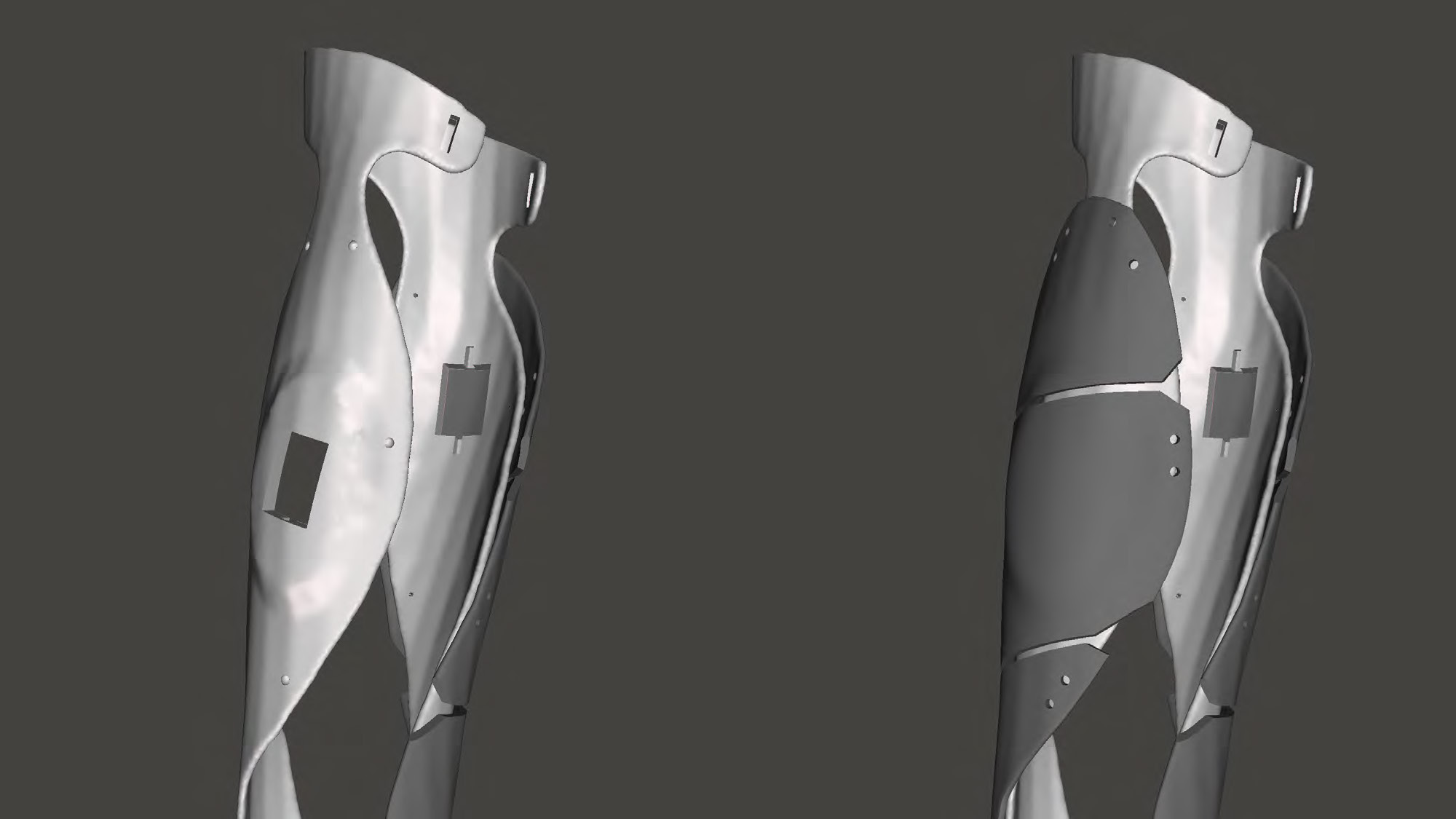

Two side-by-side 3D renders of a human forearm prosthetic. The render on the left is a shiny, metallic-looking version with cutouts, revealing internal components. The render on the right shows a two-tone version of the same prosthetic, with the main body in a dark gray and the outer shell in a lighter metallic gray. Both renders are on a gray background.

Slide-19

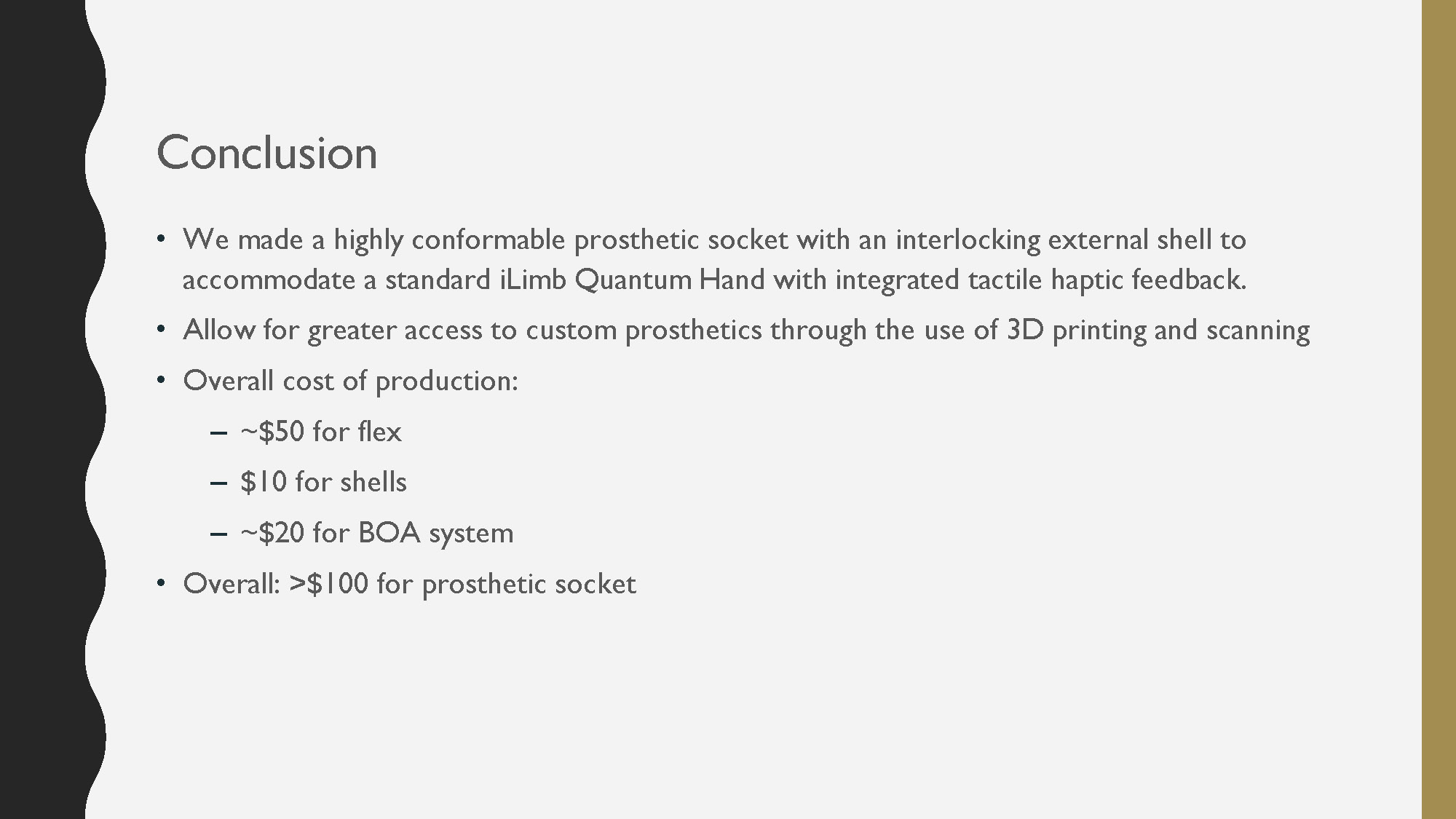

Conclusion

- We developed a highly conformable prosthetic socket with an interlocking external shell to accommodate the iLimb Quantum Hand and integrated tactile feedback.

- Allow for greater access to custom prosthetics through the use of 3D printing and scanning

- Overall cost of production:

- ~$50 for flex

- $10 for shells

- ~$20 for BOA system

- Overall: >$100 for prosthetic socket

Slide-20

Sources

- Sun-Sentinel article

- All3DP article

- Kanitz, Gunter, et al. "Compliant prosthetic wrists entail more natural use than stiff wrists during reaching, not (necessarily) during manipulation." IEEE Transactions on Neural Systems and Rehabilitation Engineering (2018).

End of Presentation

Click the right arrow to return to the beginning of the slide show.

For a downloadable version of this presentation, email: I-SENSE@FAU.